June 10, 2009

Standardization of High speed, Longer life New Spherical Roller Bearing ‘ULTAGE Series’

[Achieving world's highest load carrying capacity and permissible rotational speed through internal design optimization]

NTN Corporation (hereafter NTN) has standardized a new type spherical roller bearing ‘ULTAGE series’ achieving world highest load carrying capacity and permissible rotational speed through design optimization as well as reviewing bearing internal design. NTN will begin to sell this new series of bearings in February 2009.

For this new bearing, roller diameter and number of rollers are maximized to secure world highest load carrying capacity, and pressed steel squirrel type cage with high rigidity and precision is used to attain the world highest permissible rotational speed.

In addition, special heat treatment is applied to meet a wide range of operating using temperature up to 200°C.

This new series of bearing enable to meet all the needs, ‘Longer life’, ‘High speed’ and ‘Easy handling’ required for every kind of industrial machinery.

Current standard products (B type) will be replaced sequentially by this new type from February when the sales of new bearings starts up.

[ Features ]

| 1. | World highest load carrying capacity | |

| a. | Basic dynamic load rating: increased by max. 65% (compared with NTN's conventional product) | |

| b. | Basic static load rating: increased by max. 35% (compared with NTN's conventional product) | |

| c. | Longer life: max. 5 times (compared with NTN's conventional product) | |

| 2. | World highest permissible rotational speed | |

| a. | Permissible rotational speed: increased by max. 20% (compared with NTN's conventional product) | |

| 3. | Standard use of high rigidity and high precision pressed steel squirrel type cage | |

| a. | Newly designed pocket tabs (protrusions at 4 locations) secure stable posture of rollers during operation. | |

| b. | New cage pocket configuration provides stable supply of lubricant inside cage. | |

| c. | Special surface treatment applied to all the cage surfaces improves wear resistance property. | |

| d. | Bering handling property during assembly and disassembly is improved by design restraining roller fall-off from cage. | |

| 4. | Downsizing and weight reduction | |

| High load carrying capacity contributes to space saving, downsizing and weight reduction. | ||

| a. |

Bearing volume reduction: 30% less, when compared with NTN's conventional product Ex.) 22220B:φ100×φ180×46 810cm3 ⇒ 22218EA:φ90×φ160×40 550cm3 |

|

| b. |

Bearing mass reduction: 30% less, when compared with NTN's conventional product Ex.)22220B:φ100×φ180×46 4.95kg ⇒ 22218EA:φ90×φ160×40 3.28kg |

|

| 5. | Standard use of oil hole | |

| Oil groove and oil hole are provided on outer ring outer diameter surface as standard.. | ||

[ Applications ]

General industrial machinery: Earth moving equipment, Steel making equipment, Window power generator, Paper making machine etc.

[ 3D figures for comparison of downsizing ]

|

|

|

| [NTN's conventional product: 22220B] | [New product: 22218EA] |

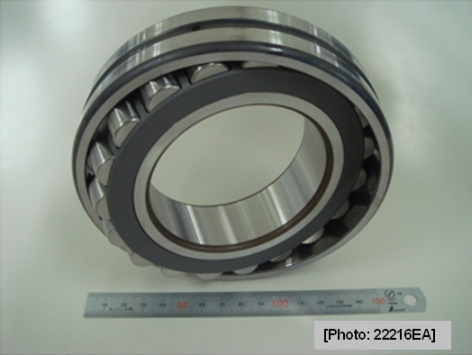

[ Product photo ]