February 4, 2008

Development of Mono Drive Two Way Feeder for Electronics

20% greater discharge capacity with a 66% space saving and 50% energy saving vs. conventional design

The Mono Drive Two Way Feeder for Electronics is a refinement of the NTN Mono Drive Two Way Feeder (hereafter MD2 Feeder) for use with electronic chip components. The MD2 Feeder for Electronics uses a high frequency oscillation to move components through the feeder.

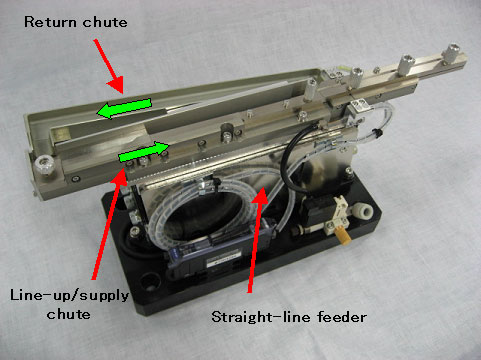

The MD2 Feeder for Electronics brings the space saving qualities first developed in the MD2 Feeder to the electronics industry. Existing feeders usually combine a bowl feeder with straight-line feeder. The MD2 Feeder for Electronics is composed of a pair of chutes and a controller that simultaneously regulates the amount of vibration in both the line-up/supply chute and the return chute. The MD2 Feeder for Electronics circulates electronic parts through each chute and supplies the lined-up parts to assembly equipment.

Through the use of MD2 technology installation space is reduced to 1/3 when compared to conventional supply equipment (bowl feeder plus straight-line feeder) while keeping the unit easy to maintain. By using a two-way line-up/supply chute the efficiency of the feeder was increased and the discharge capacity was improved by a factor of 1.2. Additionally, due to the elegant design the line-up/supply chute is easily changed making the MD2 for Electronics useful in high-mix, low-volume production.

The MD2 Feeder for Electronics was exhibited at the “2007 Parts Feeder Exhibition” held in Tokyo Big Site from November 28 (sponsored by The Nikkan Kogyo Shimbun, Ltd.).

| *1: | Feeder: a piece of equipment that transfers parts by vibrating a bowl or linear chute using magnets, hydraulics etc. as a driving source. |

| *2: | The MD2 Feeder was given the Third (FY 2005) Manufacturing Parts Grand Prix, Machine Parts Award (sponsored by The Nikkan Kogyo Shimbun, Ltd. |

| *3: | Chute: component of a feeder that provides path for parts to follow. |

[ Features ]

| (1) | Driving two chutes (line-up/supply and return chutes) in two directions by means of a high frequency vibration with one unit of straight-line feeder When compared to the convention bowl and straight-line feeder the new MD2 Feeder results in the following savings: |

|

| · | Space-saving : about 1/3 the size | |

| · | Weight reduction : about 1/3 the weight | |

| · | Energy-saving : about 1/2 the consumed electricity | |

| · | High discharge rate : 1.2 times improvement[ 4000 pieces/min for 1005 size (1.0×0.5mm)] | |

| (2) | Due to the ease with which the line-up/supply chute can be replaced the Mono Drive Two Way Feeder is suitable for high-mix low volume production | |

[ Product Photo ]