January 31, 2008

Delivery of Mass Produced Ball Screw Unit for Continuously Variable Valve Mechanism Has Begun

Contributes to the improvement of engine performance for the environment!

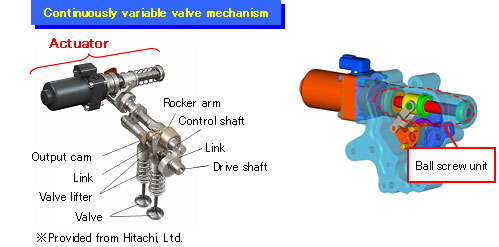

NTN Corporation (hereafter NTN) has developed a ball screw unit for an electric actuator mounted on a continuously variable valve mechanism of the automobile, and has begun mass production delivery of this VEL*1 mechanism to Hitachi, Ltd. Automotive System Group.

In order to respond to market demands for improved fuel efficiency and cleaner exhaust gas of automobile engines, a mechanism which enables continuous change to valve lift*2 and operation angle (event)*3 is required. The actuator drive parts in these mechanisms utilize a worm gear or a planetary roller screw. However, the mechanism becomes complicated or requires the use of a large motor to overcome friction. Substitution of a ball screw on the other hand offers small frictional losses, high efficiency and compactness, but historically has been cost prohibitive.

The developed ball screw unit made it possible to reduce machining man-hours by precision machining the nut groove and through the use of a special induction hardening process that restrains oxide scale generation. As a result, its price competitiveness is improved. Furthermore, from a technological aspect, together with improvement of durability through modifications of the deflector shape (new circular type), the element to circulate the ball inside the nut, and the material, crimping retains the shaft screw support bearing. Applying these new technologies to the ball screw results in reduced rolling resistance and a more compact, responsive actuator.

NTN considers the highly efficient ball screw to be in line with the trend of increasing electric components in vehicles, and will expand sales with proposing this technology to customers and products beyond those of continuously variable valve mechanisms.

| (*1) | VEL | : | Variable valve Event & Lift |

| (*2) | Valve lift | : | Distance that the valve is apart from valve seat plane |

| (*3) | Valve event | : | Range of angle of crankshaft when the valve is open |

[ Features ]

| (1)Low cost | : | Adoption of various new processes |

| (2)Low friction | : | Size reduction of motor, electric power saving and higher response of continuously variable valve mechanism |

| (3)High durability | : | Durability criterion of more than 300,000 km was cleared |

[ Application ]

Continuously variable valve mechanism and various actuators for automobile

[ Product Photo ]

[ Locations where the product is used ]