December 4, 2008

Development of ‘Air-Oil Lubrication High Speed Cylindrical Roller Bearing’ for Machine Tool Main Spindles,

[attaining the world's highest speed1) of 3.25 million dmn value2) by use of ceramic inner ring and new cage guide method]

NTN Corporation (hereafter NTN) has developed a ‘High speed cylindrical roller bearing’ for machine tool main spindle applications, enabling the world's highest rotational speed under air-oil lubrication, which is similar to that of angular contact ball bearings.

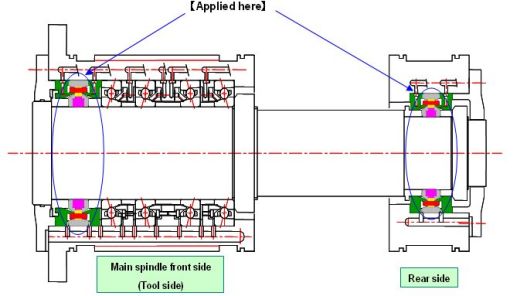

For the high speed main spindles of machining center and complex machine tool, duplex angular contact ball bearings are generally applied to the front side and cylindrical roller bearing for the rear side. For milling main spindles of the recent complex machine tools, cylindrical roller bearings in addition to duplex angular contact ball bearings are in some cases used for the front side in order to increase the stiffness of main spindles. In those cases, high-speed capability similar to that of angular contact ball bearing is also needed for the cylindrical roller bearing, and the improvement therefore becomes necessary.

Hence, having focused on the following two subjects, NTN has been successful in the development of a new cylindrical roller bearing with the world's highest speed capability of 3.25-million dmn value under air-oil lubrication, which is similar to that of an angular contact ball bearing.

| 1. | Cage guide method: A new method that guides the cage bore surface on the outer diameter surface of stationary air-oil nozzle is adopted. In this method, high temperature oil does not stay, but relatively low temperature fresh oil always lubricates the guide surface. This improves the high-speed rotational performance. |

| 2. | Containment method of excessive preload: In order to curb heat generation due to excessive preload caused by thermal expansion and centrifugal expansion of inner ring during high speed operation, a ceramic inner ring is used and at the same time a new method is adopted to ease stress generating during high speed rotation, that is, press-fitting side rings onto both ends of inner ring. Those side rings also function as inner ring ribs. These lead to the improvement of high-speed rotational performance. |

NTN will exhibit this new bearing for reference at ‘The 24th Japan International Machine Tool Fair’ (JIMTOF2008), held at the Tokyo Big Site from October 30th, as a ’Technological proposal supporting MONOZUKURI for the next generation ~ Challenging to ultra high speed and high stiffness’.

[ Features ]

| 1. |

High speed rotational performance similar to that of ultra high speed angular contact ball bearing: World's highest speed of 3.25 million dmn under air-oil lubrication. (Improved significantly by 40%, compared with NTN's conventional air-oil lubrication) [Bearing bore dia. is φ70mm and speed 35,000min-1] |

| 2. |

Improved stiffness: Bearing stiffness is improved by approx. 30% (In case ceramics are used for rollers and inner ring.) |

| 3. |

Improvement of work efficiency: Working efficiency of bearing mounting significantly improved. (Fitting interference between ceramics inner ring and steel shaft is reduced by 80%, in compared with conventional product.) |

[ Application ]

Support bearings for machine tool main spindles. (Machining center, complex processing machine etc.)

[ Reference ]

|

1) World highest speed: As of September 2008 (investigated by NTN) 2) dmn value = dm (Bearing pitch circle dia. in mm) × n (Rotational speed in min-1) Ex.: When a bearing of dm = 100mm runs at n = 50,000min-1, the dmn value is 100×50,000=5 million |

[ Product photos ]

[ Example of application: Machine tool main spindle ]