October 2, 2008

Development of the Minimum Quantity and Cooling Lubrication (MQCJ) Method for Single Row Cylindrical Roller Bearings for Machine Tool Spindles

[Enabling one of the fastest oil lubrication speeds in the world!]

NTN Corporation (hereafter NTN) has developed a new jet lubrication system for use with single row cylindrical roller bearings mounted on machine tool spindles. The new Minimum Quantity and Cooling Jet (MQCJ) lubrication system enables the achievement very high rotational speeds in machine tool spindles.

In recent years many manufacturers have been increasing the speed of the main spindles in their machine tools to improve the processing efficiency and surface quality of the work piece. Current conventional jet lubrication designs use large amounts of lubricating oil (L/min) for both lubrication and cooling purposes. Large amounts of oil are forcibly fed into the bearing for reliable performance. Unfortunately the amount of oil needed for this system creates significant drag in the bearing resulting in large power losses to the main spindle. A larger drive motor is then required to overcome this power loss.

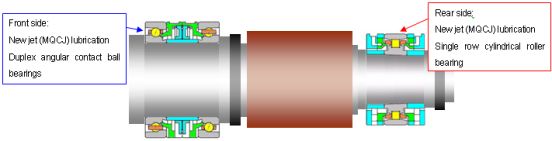

Four years ago, in an effort to address these problems NTN developed the MQCJ lubrication system. The MQCJ lubrication system directs most of the lubricating oil to the inner ring for cooling purposes. By controlling the geometry of the oil inlet nozzle and inner ring only the amount of oil needed to lubricate the bearing is supplied to the rolling elements. Two years later NTN successfully applied the MQCJ system to angular contact ball bearings.

When the new MQCJ lubrication systemwas applied to a single row cylindrical roller bearing the ultra high dmn value of 3.35 million1) was achieved. By applying the new MQCJ jet lubrication system to the cylindrical roller bearing found at the rear side of many main spindles power losses from the bearing can be cut in half and the design can be simplified when compared with the conventional jet lubrication.

The new MQCJ lubrication technology for ultra high-speed single row cylindrical roller bearings will be displayed at JIMTOF 2008 (Japan international machine tool exhibition) to be held at the Tokyo Big site from October 30th.

[ Features ]

| a. | One of the worlds fastest high-speed operations: Maximum 3.35 million dmn value, an improvement of 45% compared with conventional air oil lubrication. For example a bearing with a bore of 55 mm will have a maximum rotational speed of 45,000 rpm. |

| b. | Power loss is reduced by 50% when compared with conventional jet lubrication |

| c. | Simplified oil feed/drain system (Cooling oil for outer cylinder and lubrication oil for bearings are the same) |

[ Applications ]

Ultra high-speed main spindles for machine tools, machining centers for die processing & aluminum processing

[ Reference ]

| 1) |

dmn value = dm (Bearing pitch circle diameter, mm) × n (Rotational speed, min-1) Ex.: When a bearing of dm = 100mm runs at n =50,000 min-1, dmn value is 100×50,000 = 5 million |

[ Photo ]

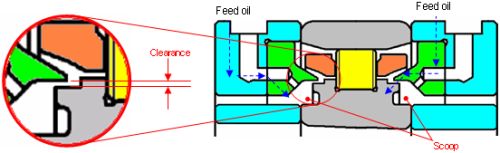

Figure 1: Cross Section of Cylindrical Roller Bearing with MQCJ Lubrication

Figure 2: Representative Cross Section of a Machine Tool Spindle

How the new MQCJ lubrication system is applied to a single row cylindrical roller bearing

In the MQCJ lubrication system oil fed through nozzles is sprayed against a scoop on the inner ring side face. Most of the oil acts to cool the inner ring. By controlling the clearance between the inner ring and nozzle spacer only the amount of oil needed to lubricate the roller elements (a fraction of the oil supplied) reaches the inside of the bearing. The oil is suctioned by a drain pump and reterns to an oil collection tank and circulated back to the bearing through a cooling oil supply unit. At the same time, the oil is also circulated to cool down the outer cylinder.