|

November 21 2005

NTN Develops Hybrid Grease Filled Bearings

for Automotive Electrical Instruments and Other Devices

NTN Corporation has developed a new hybrid grease-filled bearing that is long-lasting at high temperatures, for use in automotive electrical instruments and other devices.

In recent years, bearings for automotive electrical instruments are being used in increasingly severe environments. In order to ensure the lifetime grease in high-temperature environments, older greases used thickening agent and base oil made of fluorinated compound. The newly developed NA204F hybrid grease, however, consists of a mixture of fluorine and urea grease in an optimum ratio. Also included are appropriate amounts of anti-rust and extreme pressure agents. This enables the grease to last longer than existing fluorinated grease at temperatures of 200°C. Anti-rust protection is improved while leakage of grease is reduced.

In tandem with the development of NA204F hybrid grease, NTN has also developed a new fluorine rubber called NUF (NTN anti-Urea Fluorine Rubber). NUF rubber seals are not degraded by urea grease at high temperatures.

Bearings that combine NA204F hybrid grease with the new fluorine-rubber NUF seals are called "hybrid grease filled bearings with long lifetime at high temperatures." NTN plans to market the bearings globally, targeting automotive high-temperature electrical applications, such as fan clutches, magnetic clutches for car air conditioners, and alternators.

[Features]

-

Long life at high temperatures

-

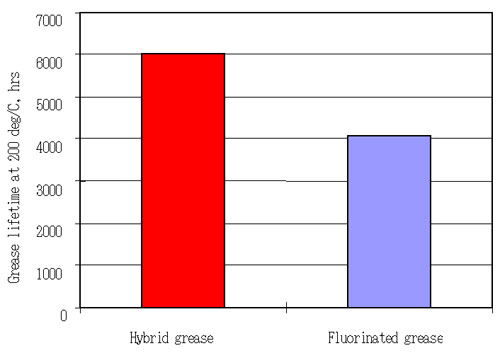

At high temperature (200°C), the grease has 1.5 times the life of fluorinated grease.

-

Improved rust prevention

-

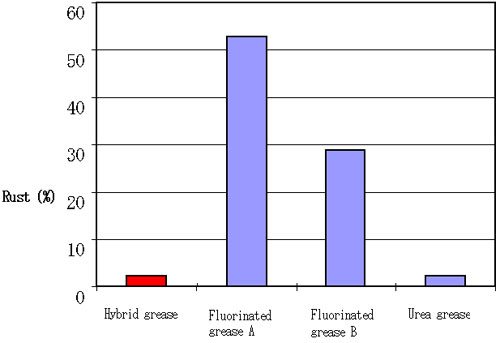

Rust prevention performance is superior to that of fluorinated grease, and is equivalent to urea grease.

-

Reduced initial grease leakage

-

Initial grease leakage is less than 1/3 that of fluorinated grease, and nearly equal to urea grease.

-

Seal rubber has no degradation issues

-

Combined with the newly developed urea-resistant fluorine rubber, NUF eliminates rubber degradation upon curing.

[Application]

- Automotive electrical instruments (fan clutches, magnetic clutches of car air conditioners, alternators, etc.)

[Product Features]

| Long life at high temperatures: |

1.5 times the life of fluorinated grease at high temperatures (200°C) |

| Rust prevention: |

Equivalent to urea grease and much better than fluorinated grease |

| Initial leakage: |

Equivalent to urea grease and less than 1/3 of fluorinated grease |

| Noise under engine cooling period: |

Equivalent to special-purpose grease (no discernable noise under engine cooling period) |

| New seal rubber: |

Urea-resistant rubber does not degrade upon curing |

Figure 1. Grease Lifetime at High Temperature (200°C)

Figure 2. Rusting

[How we achieved results]

Developed a hybrid mixture of fluorine and urea grease, while adding compound to enhance the low-temperature characteristics of the base oil.

Result: Longer high temperature bearing life, and improvements over other weaknesses of fluorinated grease!

|

Developed a new NUF fluorine rubber with improved urea resistance

Result: Long-term stable seal without impact from urea components! |

|