|

|

NTN Develops"Tapered Roller Bearings Used Exclusively for

Sprockets in Traveling Reduction Gears" for Hydraulic Excavators

The Goal is to set a Global Standard by

"Ensuring the Rigidity and Reducing the Size of Bearings

to Contribute to Downsizing of Components!"

NTN Corporation has succeeded in developing "Tapered Roller Bearings Used Exclusively for Supporting Sprockets in Traveling Reduction Gears" for hydraulic excavators, which ensures the rigidity and downsizing of the bearings. The world's top manufacturer of bearings for construction machines, NTN Corporation is planning to expand its sales operations of the bearing by positioning it as a "global standard" in the field of construction applications.

The traveling reduction gear system to drive crawlers is one of the essential components in a construction machine. An extremely high degree of reliability and durability is demanded for the bearings used in such systems. Furthermore, in correlation with the downsizing trend of components in recent years, there has been a strong demand for further downsizing of bearings.

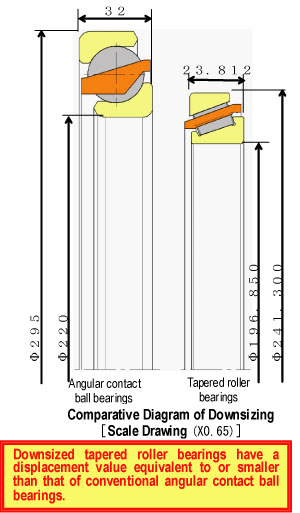

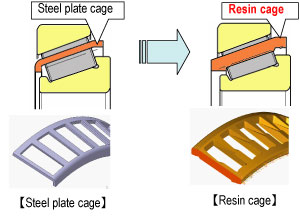

Now, a new proposal from NTN: a changeover from the existing angular contact ball bearings to tapered roller bearings. The great advantage of a tapered roller bearing is that it has far greater rigidity and load capacity than does an angular contact ball bearing. This makes it possible to downsize bearings while maintaining the current required level of rigidity. Furthermore, we have been able to suppress increase in costs by altering the material for cages from steel plate to resin with superior cost effectiveness.

The newly developed bearing is a product that can satisfy the needs of the customers by contributing to downsizing of components achieved through the changeover from angular contact ball bearings to this product. The NTN Corporation is projecting to expand its sales promotion activities for construction machinery manufacturers throughout the world to increase its sales by positioning it as a "global standard" in the field of construction applications.

[Features]

|

(1)Downsizing and Weight Reduction of Bearings ⇒ Downsizing of Components

|

|

|

[Applications]

Integration into the sprocket supporting section of the traveling reduction gears for hydraulic excavators

[Application of the specifications will begin in 2 classes of hydraulic excavators: 20 and 30 ton classes.]

[Photograph of product]

[Improvement Points]

- Assignment (1): Downsizing of bearings

Method: Switch-over from angular contact bearings to tapered roller bearings

|

- Assignment (2): VA / VE (Cost-cutting)

Method: Switch-over from steel plate cages to resin cages

|

|

|

[Investigation Results of Rigidity of Bearing]

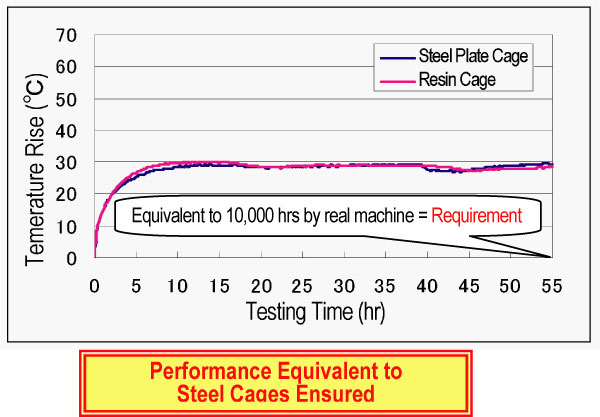

[Test Results for Evaluation]

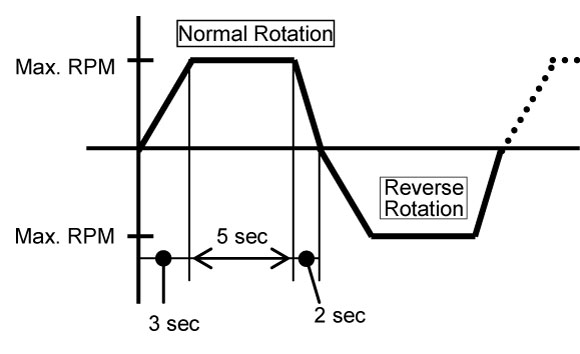

< Endurance Test under Max. Acceleration on Real Machine >

| |

|

|

|

|

Loading Condition

Maximum condition for usage on real machine:

Radial Load + Axial Load

|

|

|

|

|

|

|

|