NTN Develops "Hybrid Bearphite" High-Precision Low-Friction Sliding Bearings and Starts Mass Production

[Plastic & sintered metal hybrid bearing materials achieve high-precision and low-friction]

By adopting a completely new concept of hybrid structure, NTN has developed "Hybrid Bearphite" sliding bearings that combine the advantages of both plastic material and sintered metal resulting in both high precision and low friction. In addition, soft shaft materials can be used with this bearing. Mass production of this new bearing design has already begun for major photocopier manufacturers.

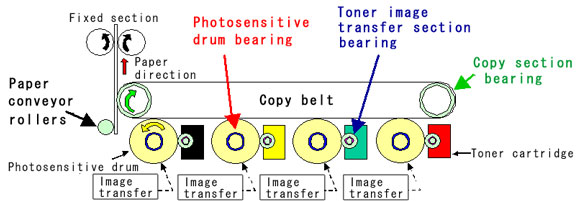

Printers and photocopiers use various types of bearings for their rotating parts (Figure 1) (Table 1). Compared with sliding bearings, rolling bearings have superior rotational precision, torque and durability. However, one drawback is that they are expensive. Oil-impregnated sintered bearings are less expensive than rolling bearings. In addition, they have superior rotational precision and lower torque than plastic sliding bearings. In applications where the rotation speed is low, an oil film on the sliding surface cannot form, so sintered bearings have a tendency to allow wear on shafts made of soft material. On the other hand, plastic sliding bearings are the least expensive option and using the proper material composition, aluminum or other soft metals can be used as the shaft material. However, these plastic materials have drawbacks such as a large shrinkage ratio during molding, a large coefficient of linear thermal expansion and poor dimensional precision and stability. Therefore, in locations such as the photosensitive drums, where rotation precision affects print quality, more expensive rolling bearings have been used because bearing function takes priority over cost.

Figure 1: Basic Photocopier Structure

|

Table 1: Characteristics of Photocopier Bearings

|

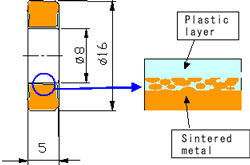

Figure 2: Hybrid Bearphite Concept

|

To replace these relatively expensive rolling bearings, NTN has developed "Hybrid Bearphite" high-precision low-friction sliding bearings which are created by forming a thin layer of plastic sliding material on the inner diameter surface of the sintered metal backing. Figure 2 shows a schematic diagram of this new design. Since the plastic layer is formed by injection molding, the productivity is good, the required product precision (circularity 10 µm max.) is met and the cost of traditional rolling bearingis reduced by approximately 30%.

Since the plastic layer is only 0.25 mm thick, expansion and contraction due to temperature change is small. Therefore, high precision is maintained over a wide temperature range (10-60°C). Furthermore, by combining the plastic with a special filler, an extremely low friction coefficient (µ) of 0.05 (1/2 the friction coefficient of conventional plastic sliding bearings), was achieved, resulting in low rotational torque. Also, since the plastic layer is formed on the width surfaces as well as the bore, it can receive the axial load as well as the radial load.

Normally, when a plastic layer is formed on metal, there is a potential for the plastic layer to peeling away from the metal due to the difference in their thermal expansion coefficients. Since "Hybrid Bearphite" bearings use sintered metal for the backing material, the plastic adheres to the pores of the sintered metal, reducing the probability of peeling. The strength of this adhesive force provides superior dimensional precision and durability.

Lastly, since the structure of the "Hybrid Bearphite" bearing is so simple, there is no need to enlarge the sectional thickness, as is frequently needed for rolling bearings. Therefore, the customer can incorporate a much more compact design with the "Hybrid Bearphite" bearing.

[Features]

- (1) High rotational precision equal to that of oil-impregnated sintered bearings.

- This is accomplished by molding a thin layer of plastic onto the bore and sideface surfaces of a sintered metal inner diameter.

- (2) Low friction [friction coefficient (µ) of 0.05]

- A material with high sliding performance is used as the plastic on the inner diameter to attain a friction coefficient half of conventional plastic. This is the lowest friction level available in the world.

- (3) Aluminum and other similar soft materials can be used for the mating shaft.

- (4) Thanks to their low price and compact design, they are ideal for replacing rolling bearings.

[Sizes available]

Bore diameter x Outer diameter x Width (JIS part number designation)

Φ6×Φ12×4 (WBC6-12), Φ8×Φ12×3.5 (W678), Φ8×Φ16×5 (W688), Φ10×Φ15×4 (6700), etc.

Specially ordered dimensions are also available.

|