NTN Exhibits at the 20th Motion & Power Transmission ExhibitionJuly 6, 2011

| Date & Time | July 20 (Wed) to 22 (Fri), 2011 10:00 to 17:00 |

|---|---|

| Venue | Tokyo Big Sight (Ariake, Tokyo International Exhibition Center) |

| Organizer | Japan Management Association |

| NTN Booth | 1D-211 (East Hall 1) |

With the theme of “Proposing technology to support future industries,” NTN Corporation (hereafter, NTN) will have on display a number of new products and systems in four main zones ((1) EV system-related products (2) Bearing-related products with integrated sensors (3) Composite material-related products (4) New bearing-related products).

Main Highlights

- EV system-related products

- In-Wheel Motor System

- One Motor Type EV Drive System

- Bearing-related products with integrated sensors

- Integrated Rotation Sensor Sliding Bearing

- Composite material-related products

- Hydrodynamic Twin Bearphite

Main exhibits

In-Wheel Motor System

[ Features ]

NTN's unique next-generation drivetrain for EVs

- An in-wheel motor unit with a high reduction ratio, efficiency and load capacity by combining a cycloid speed reduction mechanism with a compact, lightweight motor.

- An integrated multi axis load sensor enables detection of vehicle behavior from the tires, which allows road conditions to be detected and the vehicle to be controlled simultaneously.

- The drivetrain of conventional internal combustion engine-powered cars is no longer required, providing more freedom for car designs.

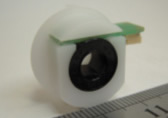

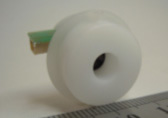

Integrated Rotation Sensor Sliding Bearing

[ Features ]

With integrated resin sliding bearing

- Combines an integrated resin sliding bearing and a magnetic type rotation sensor in a single easy-to-use unit, allowing for more compact designs for various equipment and devices.

- The use of flexible connectors means wiring direction can be selected at will.

- A wide range of input voltages (3 - 26 V) means it can be used for various machinery and specifications.

- No restrictions to the shape of the bearing and product outer diameter, meaning the product can be fully customized.

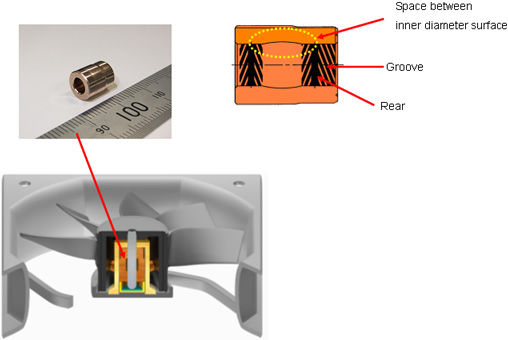

Hydrodynamic Twin Bearphite

[ Features ]

Lower torque by optimizing hydrodynamic bearing surfaces in two areas and the space between them

- An optimized design of the space between the hydrodynamic Bearphite inner diameter surfaces to achieve a 10% reduction in rotating torque compared to conventional products.

- Non-contact support for the rotational axis with hydrodynamic effects delivers outstanding quietness and high reliability.

- Press fitting is now possible with the outer diameter surfaces of the Hydrodynamic Bearphite for simple assembly to housings.