NTN participates in the 14th Shanghai International Automobile Industry Exhibition “Auto Shanghai 2011”April 20, 2011

| Date | April 21 (Tue) - 28 (Thu), 2011 |

|---|---|

| Venue | The Shanghai New International EXPO Center (SNIEC) |

| NTN Booth | Hall W5, Booth No. B076 |

NTN will exhibit its latest products for internal combustion engines, including products for state of the art EV, with the theme “Innovative Technology of NTN Supporting the Evolution of Vehicles”, and we are waiting for everyone to visit out booth.

Products manufactured in our plants in China and France NTN-SNR will also be exhibited, to demonstrate our support system on a global level.

Main Highlights

- Products for EVs

- Intelligent In-wheel

- One Motor Type EV Drive System

- In-wheel Motor System for 4-wheel drive Electric Commuters

- Intelligent In-wheel CG Images

- Products for Internal Combustion Engines

- Self mounting type chain tensioner

- Ultra light-weight 3rd Generation Hub Bearings for Mini Cars

-

Overseas Manufactured Products

- 3rd Generation Hub Bearings

- 1st-3rd Generation Hub Bearings, Strut Bearings

- Manufactured by NTN-SNR

Main Products Exhibited

Intelligent In-wheel

Drive train for next generation EVs advocated by NTN

[Features]

- An In-wheel motor unit with a high reduction ratio, high efficiency and high load capacity, combined with cycloid reducer and a compact and lightweight motor.

- A built-in Multi-axis load sensor, which makes it possible to detect the vehicle behavior near the tires, and achieves synchronization of the detection and vehicle control.

- Since drive train mechanisms like an internal combustion engine are not required, the vehicle body can be designed more freely.

In-wheel Motor System for 4-wheel drive Electric Commuters

Optimized for commuters, while maintaining the merits of an in-wheel type motor

[Features]

- A compact In-wheel motor module adopting thin hub bearings, and can be housed in the small diameter wheels of commuters.

- The systemized control including the drive motor, reduction gear, hub bearing and inverter, enable advanced vehicle control.

One Motor Type EV Drive System

EV power train with a systematized two-speed automatic transmission, drive motor and inverter

[Features]

- The cooperative control of the motor for the vehicle drive and a transmission actuator, allows for quick and smooth shifting.

- By selecting the appropriate transmission gear ratio according to the running state of the vehicle, even the compact and lightweight motor for the drive can accelerate smoothly, and enables high speed running. The cruising range per charge also improves.

- This total system can be proposed and offered as the “NTN-one motor type EV power train” in combination with a constant-velocity joint and a sensor integrated hub bearing, which is the advantage of NTN.

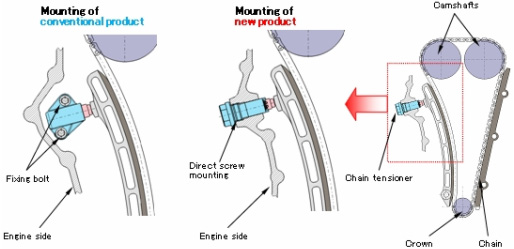

Self Mounting Type Chain Tensioner

[Features]

A timing chain tensioner which can be removed or installed from outside the engine cover

- It has a male thread on the outer diameter of the chain tensioner, and the tensioner can be installed by screwing it into the female screw hole on the engine cover.

- Compared to conventional products, compact engine designs are possible, which achieves weight reduction and reduces the number of parts.

- Since the engine cover does not have to be removed, labor hours during production or maintenance can also be greatly reduced.