JIMTOF2010 25th Japan International Machine Tool FairOctober 29, 2010

| Periods | 09:00-17:00, October 28-November 2, 2010 |

|---|---|

| Venue | Tokyo Big Sight (Tokyo International Exhibition Center) |

| NTN booth | W2007 (West 2 Hall) |

| Organizer | Japan Machine Tool Builders' Association and Tokyo Big Sight Inc. |

NTN's exhibits are divided into the following five zones that include environmental equipment as well as functional products required for the machine tools of the future. NTN's exhibition theme is “Supporting the Evolution of Manufacturing.”

| (1) Machine Tool Spindles | Our ULTAGE line of bearings for machine tools now include our high-speed angular contact thrust ball bearings and ball screw support bearing units. In addition, we offer bearings with the optimal specifications to meet functional requirements. As a result, these products can accommodate a wide range of processing conditions. |

|---|---|

| (2) New Processing Technologies | By putting unique technologies in motion, we can suggest new processing technologies for eco-friendly manufacturing. |

| (3) Products for Machine Tools | We are exhibiting pallet changers and indexing products as well as plastic bearings that can be used in water or in various solutions such as those found in ancillary facilities at processing sites. |

| (4) Intelligence | We are introducing technologies that fuse our bearing expertise with sensor technology for angle detection through small-radius, high-precision operation. |

| (5) NTN-SNR | We are introducing a maintenance kit to ensure the safest use of bearings. |

Main Exhibits

New Series 9 High-speed Angular Contact Ball Bearings

With optimized internal design for increased rigidity and allowable axial load, these ball bearings can accommodate a high load capacity.

[Features]

- [1] Extended rated life

- : 50% increase in load rating (three times the rated life of conventional products)

- [2] Increased load

- : 20% increase in allowable axial load

- [3] Improved bearing stiffness

- : The radial rigidity and axial rigidity are 1.5 times greater than those of previous products.

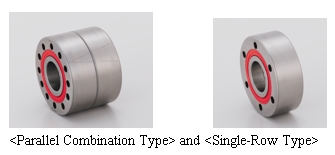

Ball Screw Support Bearing Unit (BSTU*)

This product offers a high load capacity, low torque, and the world's longest rated life.

[Features]

- [1] The world's highest load capacity

- [2] New low-torque design with standardized highly dustproof seal (resulting in only half the starting torque of competitors' products)

- [3] Initially lubricated with long-life grease, eliminating the need for in-process grease replenishment.

- [4] Can be easily mounted to a housing (the outer ring is provided with mounting bolt holes).

* Abbreviation for “ball screw support angular contact thrust ball bearing unit.”

Miniature Grinding Sludge Solidification System

With an energy-efficient and space-saving design, this system contributes to a reduced environmental impact and zero emissions.

[Features]

- [1] Incorporates an automated pressurization system.

- [2] Designed with a compact footprint (only 40% the size of the conventional PRG-I).

- [3] Offers improved workability and maintenance with a user-friendly design.

- [4] The energy-efficient design consumes 14% less power than conventional control systems.

Air-oil Lubricated Super-high-speed NU Cylindrical Roller Bearing

The use of a ceramic inner ring results in a dmn value of 3.25 million. This bearing exhibits significantly improved bearing stiffness and mounting capability.

[Features]

- [1] Super-high-speed rotation speed

- : Air-oil lubrication contributes to a dmn value of 3.25 million, a 40% improvement over conventional air-oil lubrication.

- [2] Improved bearing stiffness

- : The ceramic roller/ceramic inner ring configuration increases rigidity by about 30%, while the steel roller/ceramic inner ring configuration improves rigidity by about 7% (both in comparison with the steel roller/steel inner ring configuration).

- [3] Improved mounting capability

- : Compared to the steel inner ring configuration, the ceramic inner ring/steel shaft configuration achieves an 80% decrease in fit tolerance.