Contribute to Carbon-Free Society

The Group is focusing on five initiatives, “Contribute to spread of wind turbine and hydrogen society,” “Save energy for EVs and electrification (core products),” “Save energy for EVs and electrification (new areas),” “Increase efficiency of manufacturing equipment” and “Bearing refurbish business” toward a carbon-free society.

■Five initiatives that NTN Group focuses on toward a carbon-free society

Realize a sustainable society using natural energy

Contribute to spread of wind turbine and hydrogen society

In order to realize a carbon neutral society, natural energy generated using wind and solar power to generate electricity and hydrogen energy that does not emit CO2 at combustion, are attracting attention as next generation clean energy.

In the field of wind power generation, there is a growing demand for developing higher durability and reliability of components than ever before, especially in offshore wind power generation, due to the increasing size of power generation equipment and the lack of easy maintenance. In the hydrogen-related field, there is also a need to extend the service life of rolling bearings and plastic products used in hydrogen stations and other hydrogen-related infrastructure.

We will contribute to the realization of a sustainable society through product development and business initiatives.

Wind power

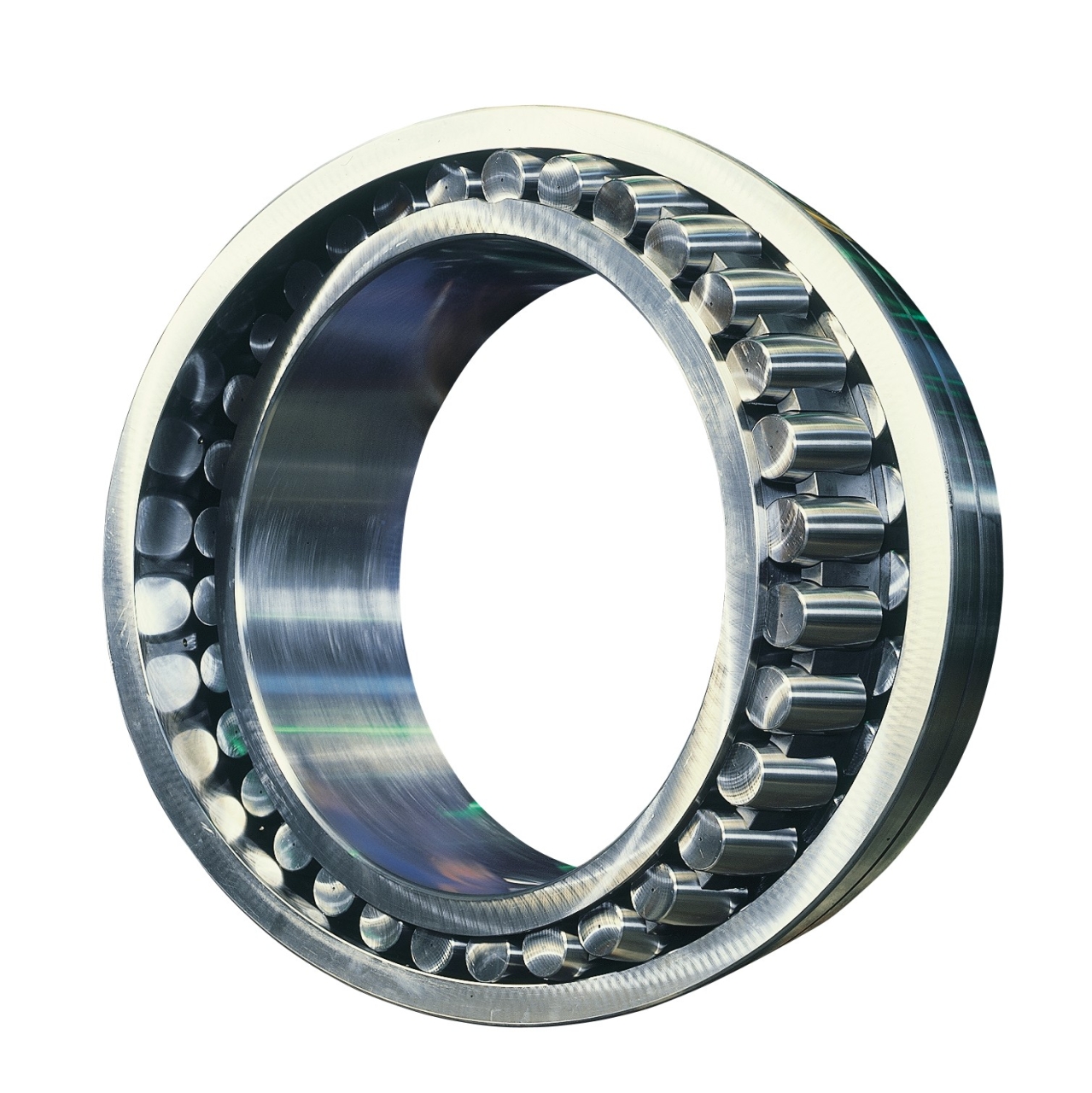

Wind power generation projects are expanding to achieve a carbon-neutral society. Especially in recent years, offshore wind turbines have been installed in sea areas with stable wind directions. Offshore wind turbines are larger than their onshore counterparts, and their components must be highly durable and reliable. In order to meet the needs, we are marketing “left-right rows asymmetrical spherical roller bearings” with a DLC (diamond-like carbon) film on the roller surface, which has excellent wear resistance, thereby enhancing the reliability of rolling bearings.

Furthermore, in order to improve the operation rate of wind power generation, we provide wind power generation operators with a service that distributes operational status using “Wind DoctorTM,” a Condition Monitoring System (CMS) for wind turbines. In 2022, we entered into a business alliance with Hokutaku Co., Ltd. (hereinafter referred to as “Hokutaku”), expanding the maintenance business for wind power generation equipment. If any abnormal trends are observed, we will distribute information to wind power generation operators that have installed our CMS and suggest the need for maintenance. After that, upon request, we will inspect the wind power generation equipment jointly with Hokutaku, identify any abnormal parts and arrange for repair bearings in a single operation. Power generation companies have received this well for our ability to provide a full range of services from abnormality detection, inspection and repair.

For offshore wind turbines, which are expected to be expanded in the future, improving the accuracy of condition monitoring and performing appropriate maintenance based on accurate data analysis will become even more critical. As a manufacturer that can provide products and services on a one-stop basis, we will contribute to expanding the wind power generation equipment market.

■Asymmetrical spherical roller bearing

■Wind DoctorTM

Hydrogen

Hydrogen is attracting attention as a next-generation energy source, and technological development is being actively pursued globally in all aspects of its utilization, including production, transport, storage and use. We are developing the application of products used in high-pressure hydrogen compressors for hydrogen stations, which are indispensable for the widespread use of fuel cell vehicles (FCVs). Mechanical parts used in hydrogen-related equipment are used in special environments such as hydrogen exposure and high pressure, requiring higher reliability and durability.

We have developed new steel material with many hard, fine metal compounds dispersed on the bearing raceway, combining them with a newly developed special heat treatment technology to develop a hydrogen embrittlement-resistant bearing that has more than three times a longer life compared to our standard bearing against premature failure of bearings caused by hydrogen and started sample prototyping and delivery.

In addition, resin products developed using our composite material technology have been adopted as sealing components for hydrogen environments. To further enhance the functionality of these products, we are also working on development in collaboration with industry and academia.

■Hydrogen embrittlement resistant bearing

Reduce energy loss

Save Energy for EVs and electrification

The electrification of cars and electric vehicles are essential to achieving carbon neutrality, and the electric drive units needed to power vehicles are becoming more sophisticated and powerful at an accelerating rate. We will contribute to energy conservation for electric vehicles by developing automotive deep groove ball bearings compatible with the miniaturization of electric drive units and the high-speed rotation of motors, as well as modular products that add energy recovery and steering functions to hub bearings.

Providing high-performance bearings (core products)

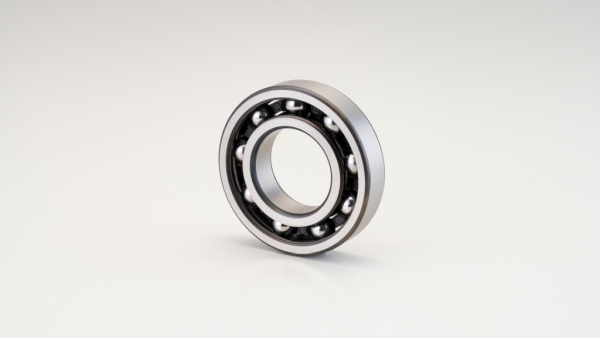

The electric drive units used in EVs and HEVs are increasingly needed to be more efficient, compact and lightweight. The development of e-axles, in which the motor is integrated with an inverter and reduction gearbox, is gaining momentum. We have already marketed “High Speed Deep Groove Ball Bearing for EVs and HEVs” with a dmn value* 1.8 million, and highly evaluated by our customers. Rolling bearings used in motors and reduction gears, which are becoming smaller and faster, are required to rotate at higher speeds. We have developed a high speed deep groove ball bearing with a dmn value* of 2.2 million under oil lubrication by optimizing the internal dimensions of the bearing through the establishment of a calculation method for the amount of oil supplied to optimize the balance of heat generated by the bearing and its lubrication conditions, and by reviewing the cage shape to suppress deformation caused by centrifugal force.

Furthermore, the housing of the drive unit is thinner, reducing the overall weight of the drive unit. “Creep phenomenon,” in which the bearing gently rotates and shifts on the mating surface between the housing and bearing, may occur due to outer ring deformation caused by the rotational load. We have developed “Creepless bearings” with a relief portion on the outer diameter surface of the bearing outer ring to make the housing and bearing mating surfaces discontinuous, thereby stopping creep and preventing abnormal noise and vibration in the equipment and reducing bearing life.

In the future, the demand for bearings in the automotive market is expected to continue to grow in response to the progress of EVs and HEVs. We will continue to enhance and develop our product lineup that anticipates market needs and contribute to the carbon neutrality of automobiles by leveraging our core competencies and incorporating next-generation technologies.

*dmn value: Index of the bearing rotational performance

Rolling element pitch circle diameter mm x rotational speed min-1

■High Speed Deep Groove Ball Bearings

for EVs and HEVs

■Creepless Bearing

Providing high-performance module products (new areas)

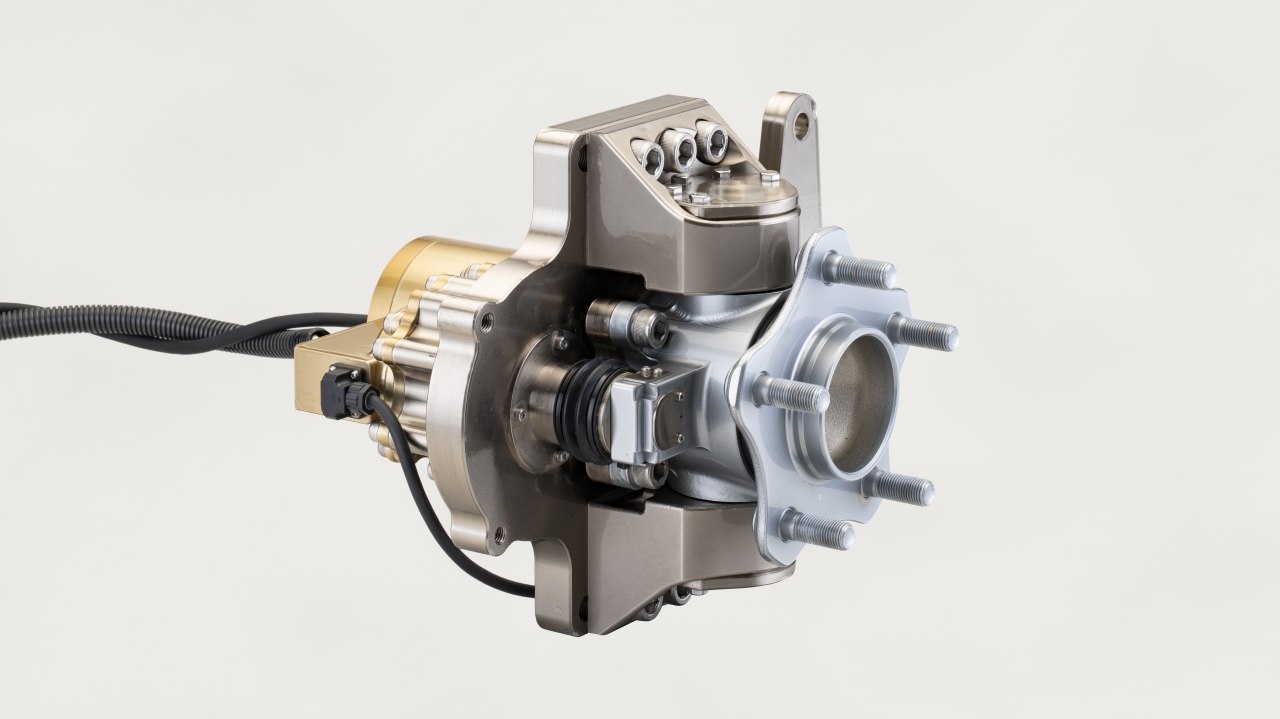

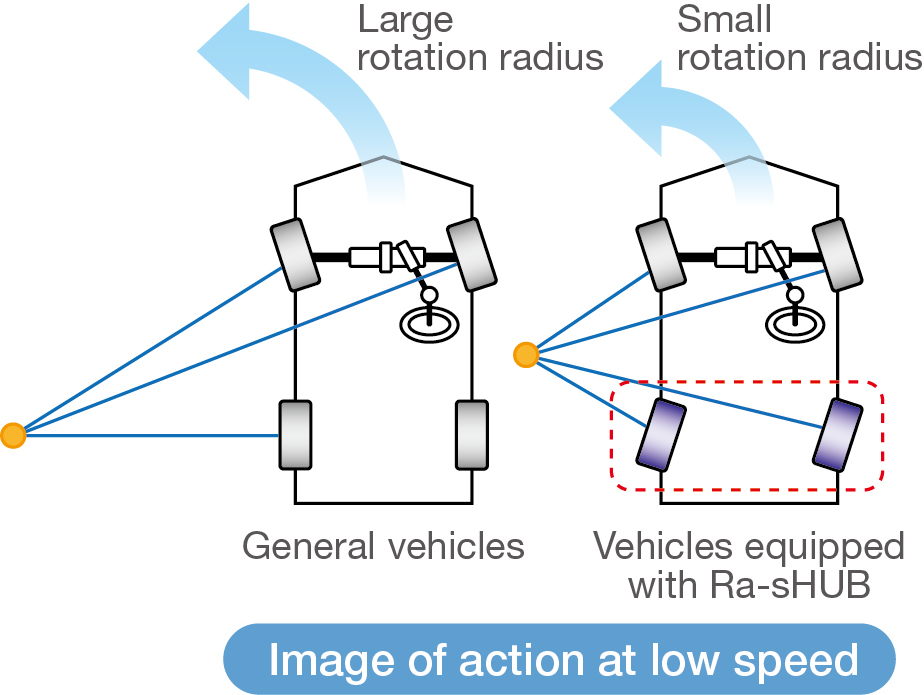

We are developing “Ra-sHUB” hub bearings with a steering function for rear wheels, which individually compensates for the steering angles on the right and left sides by making full use of the technologies we have accumulated in our hub bearings.

The rear-wheel steering systems on the market are limited to some suspension systems, such as multi-link system used in luxury vehicles, and it is difficult to achieve a large steering angle with the existing structure.

“Ra-sHUB” is a module product that adds a steering function to our hub bearings with using our proprietary technologies. They are as small as existing hub bearings, and can be mounted on any type of suspension system, to achieve rear wheel steering. By controlling the steering angle of the rear tires from the steering angle and driving information of the front wheels separately from the left and right sides, the cornering performance and high-speed straight driving stability of the vehicle can be improved. At low speeds, the minimum rotation radius can be reduced to improve the vehicle’s small turning performance and tire traveling resistance. In addition, as the level of automated driving increases, vehicle operation control must become even more sophisticated. “Ra-sHUB” also contributes to safe driving during crisis avoidance.

Characteristics of “Ra-sHUB”

- Module product with steering function for hub bearings

- Controls the rear wheel angle independently on the left and right sides

- Rotation angle +/-10 degree

- Improved cornering performance and high-speed straight driving stability of vehicles

- Reduce the minimum rotation radius of the vehicle

■Ra-sHUB

Increase efficiency of manufacturing equipment

To improve productivity at manufacturing sites, there is a desire to minimize equipment downtime by monitoring equipment operating conditions and accurately and systematically performing maintenance and parts replacement based on the data. Furthermore, in recent years, with the advancement of DX and IoT technologies, there is a growing need for remote and automatic monitoring of equipment that is not restricted by location or time, as well as the stabilization and improvement of manufacturing quality through the use of condition monitoring information obtained.

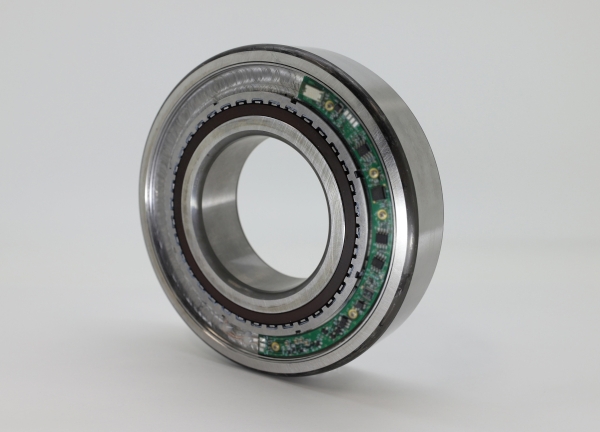

To meet these condition monitoring needs, we have developed “Talking bearingTM,” which incorporates a power generation unit and wireless communication device into a standard rolling bearing without changing the bearing dimensions or load capacity and wirelessly transmits sensing information on temperature, vibration and rotation speed. The energy generated by the rotation of the bearings is used to power sensors and wireless communication devices to transmit sensing information automatically. Because the sensor is built into the bearing, the bearing condition can be detected with greater sensitivity than when the sensor is mounted externally on the equipment housing, allowing earlier detection of abnormalities.

This newly developed product will enable advanced condition monitoring. It will help increase the efficiency and productivity of manufacturing facilities.

■Talking bearingTM

Bearing refurbish business

We are engaged in the business of refurbishing bearings used in various types of machinery and equipment, such as extra-large sized bearings for paper mill, large sized bearings for steel mill, and bearings for railway application. We provide optimal bearing refurbishing services based on our bearing technology know-how in response to these customer requirements. Furthermore, along with training on the proper use of bearings and condition monitoring services, we will expand our comprehensive approach to NTN Group’s materiality, which includes “Provide safety and comfort,” “Reduce energy loss,” and “Resource recycling and pollution prevention.”

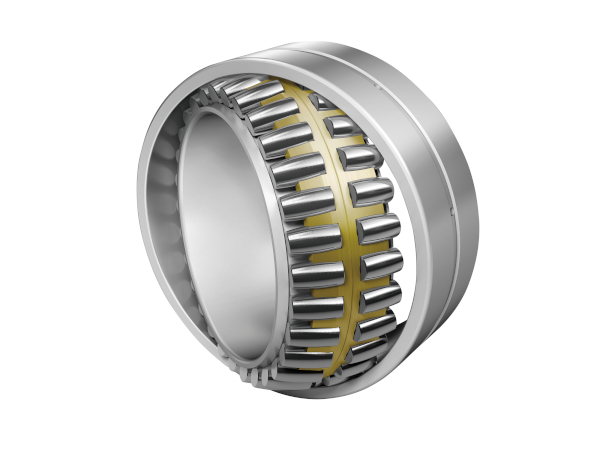

■Extra-large sized spherical roller bearing for paper mill application

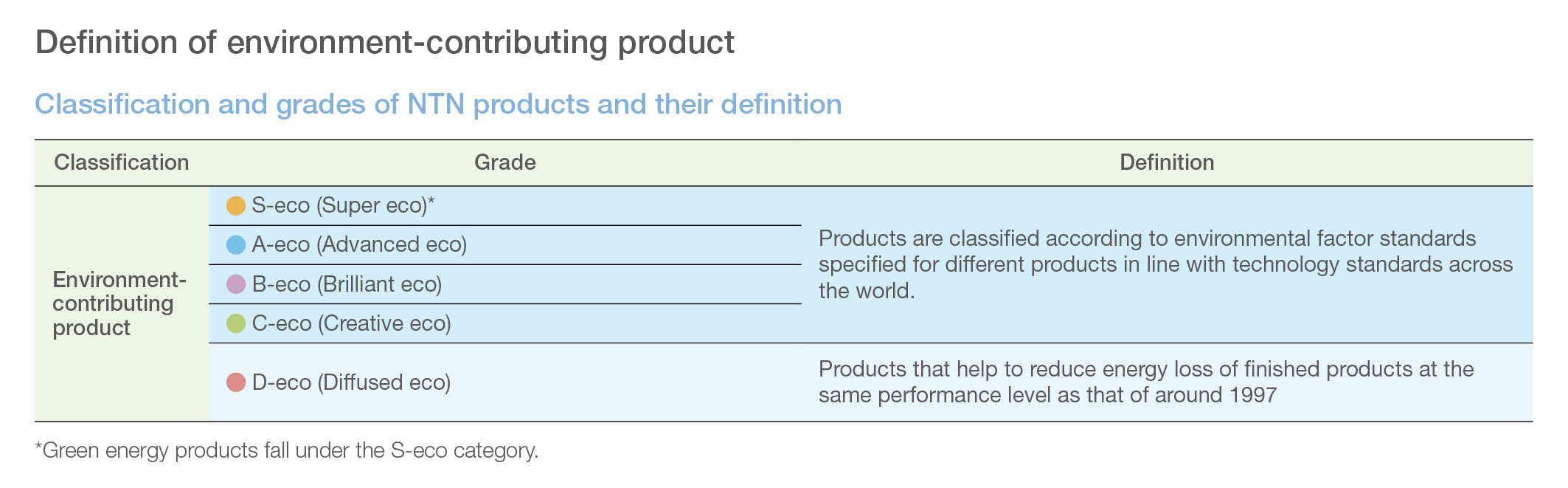

Development of environment-contributing product

We conduct our business under the corporate philosophy of “We shall contribute to international society through creating new technologies and developing new products,” the first item of our Environmental Policy is “Developing technology that contributes to prevention of global warming.” Our main products, such as bearings and drive shafts, all contribute to reducing energy loss in the finished products. They can, therefore, all be considered environment-contributing products. Some of them are already widely used in society as the achievements of our predecessors, while others have made further contributions to the environment through our technological and developmental capabilities. Moreover, green energy products are environmentally friendly and contribute to reducing CO2 emissions by generating renewable energy.

We continue unwavering efforts to realize its corporate philosophy by developing and providing higher-grade products that contribute to the environment while quantifying the degree of environmental contribution based on our standards.

Definition of environment-contributing product

Classification and grades of NTN products and their definition

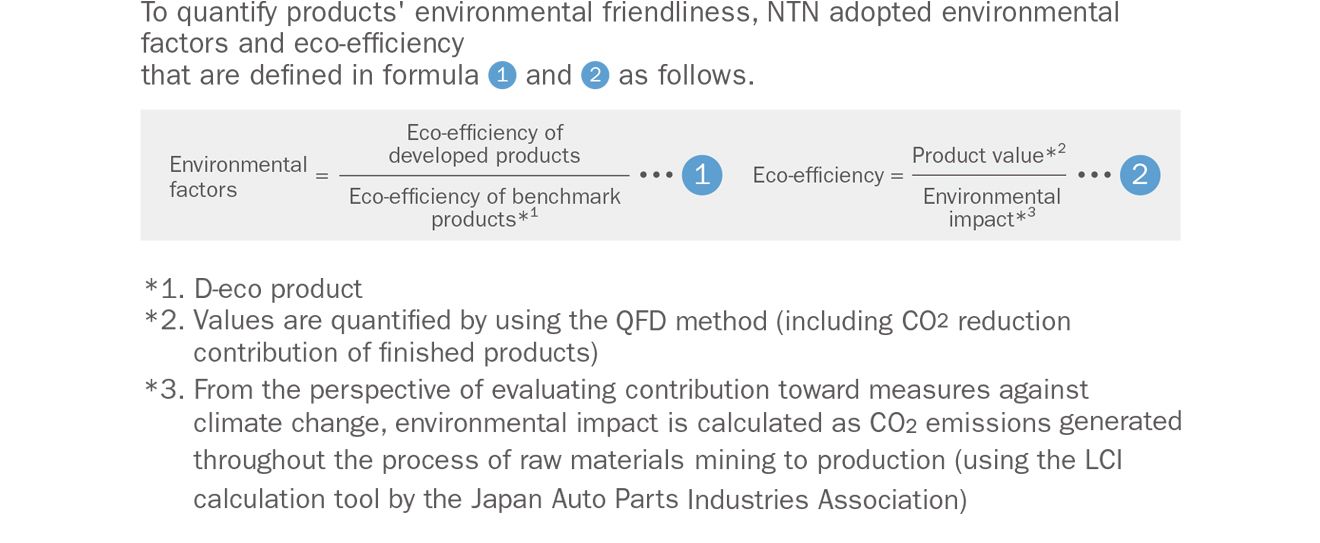

Calculation methods for environmental factors and eco-efficiency

Trend in achievements and forecasts

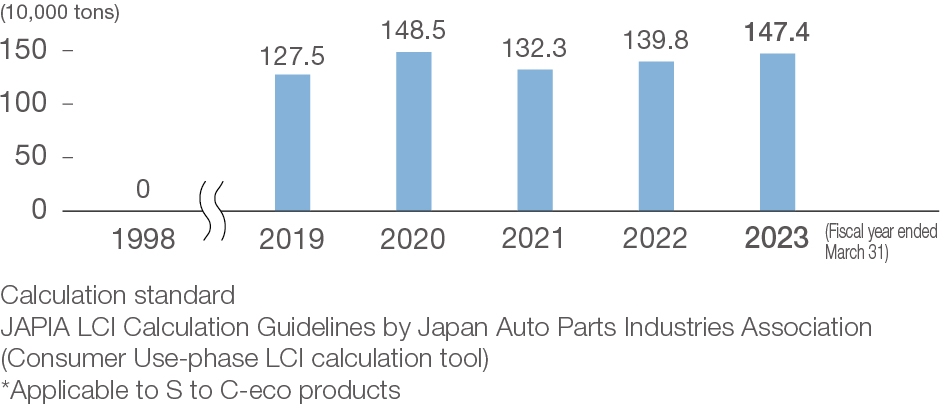

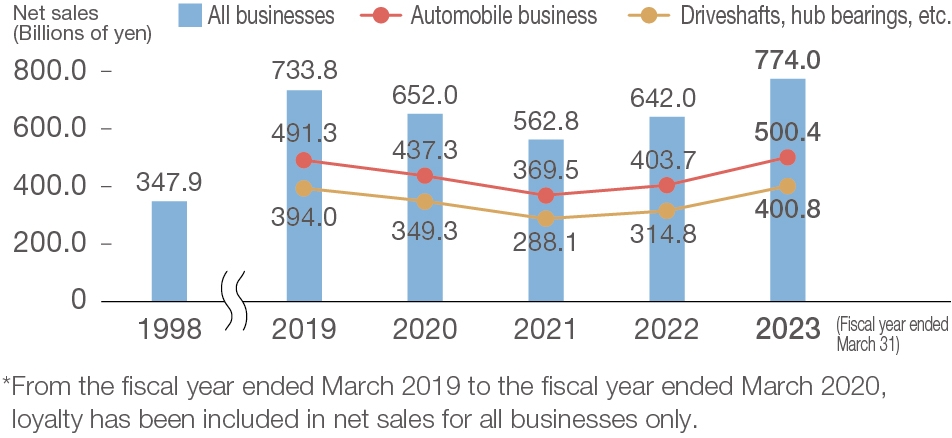

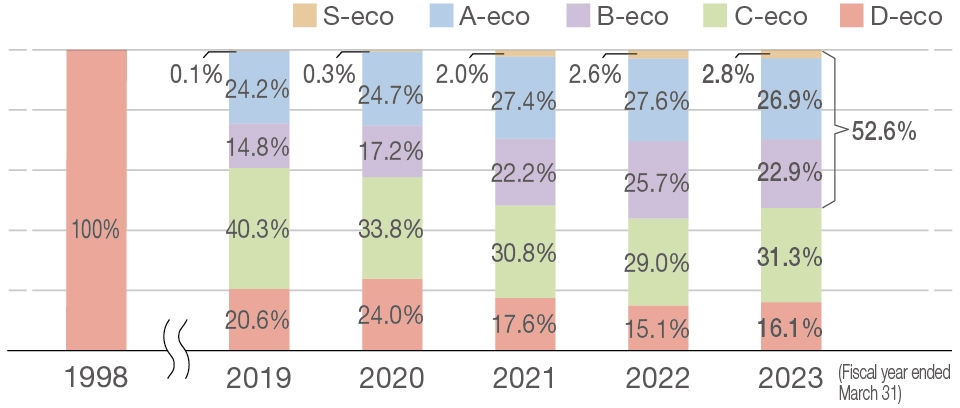

Driveshafts and hub bearings, which are our main products and account for about 50% of our net sales, and green energy products contributed 1,474 thousand tons of CO2 reduction in the fiscal year ended March 31, 2023. Sales of S- to B-eco grade environment-contributing products, which are the result of our recent development efforts, comprised 52.6% of net sales in the fiscal year ended March 31, 2023.

■Trend in net sales*

■Trend in composition of environment-contributing products by grade

(driveshafts and hub

bearings)

■Contribution to CO2 reduction*