CSR activities in FY2017

Preventing global warming

The NTN Group works on reducing CO2 emissions throughout all business activities. To guarantee its reliability, our emissions data is subjected to third-party verification by inspection and certification authority SGS Japan. We plan to increase the range of business activities certified under the Scope 3 (supply chain emissions) category.

NTN Noto Corporation installs energy-saving heat treatment equipment

NTN Noto Corporation has succeeded in saving energy by installing cutting-edge heat treatment equipment in October 2017. The equipment was installed to accommodate the creation of a integrated production system for the Hokuriku area along with an increase in the volume of spherical bearings currently being produced. The equipment reduces heating energy by using a high-performance insulation material and a heating furnace with a built-in atmosphere gas generator. Design features such as a timer-controlled pilot burner igniter reduce annual power consumption by about 1.1 million kWh/year relative to previous equipment (equivalent to an annual CO2 emissions reduction of 421 metric tons/year). The equipment improves product quality by having a structure that keeps air away from the products during each process from heating through cooling. It also uses a new heat treatment process technology to double productivity.

Okayama Works switches to city gas

The Okayama Works uses butane, kerosene and fuel oil A for heat treatment and boiler fuel, but is now switching to city gas under a 5 year plan begun in 2017. The many benefits of using city gas include lower fuel costs, simplified fuel management enabled by pipeline supply, improved safety and lower CO2 emissions (annual reduction of 2,384 metric tons).

NTN Kongo Corporation* recycles water-soluble coolant

The water soluble coolant NTN Kongo Corporation uses for its grinders previously needed a full replacement about twice per year. NTN Kongo* has now installed a coolant recycling system that recycles all used coolant. Although new coolant still needs to be added to make up for natural depletion from evaporation and other losses, NTN Kongo* has reduced its coolant consumption by 70% and completely eliminated the disposal of 10,000 liters of used coolant per year.

*Current Kongo WORKS

Kuwana Works installs VPF*tank

By installing a suction filter coolant tank, the Kuwana Works has succeeded in extending its coolant replacement frequency from 6 months to 1 year. The new tank reduces the quantity of disposed waste fluid by 40 metric tons/year. The tank’s cellulose filter aid enables grinding sludge to be remelted in an electric furnace. It can reused as iron without the need for a separation process. The equipment uses an energy-saving pump and chiller compressor with inverter control.

* VPF: Vacuum precoat filter

Grinding sludge conveyor

Upgrade to Top Runner High-voltage Transformers

NTN Mikumo Company Limited (Current Mikumo Works) has upgraded two high-voltage transformers (100 and 300 kVA) to top runner models that improve energy consumption by about 40% relative to pre-1999 JIS models. The upgrade can reduce CO2 emissions by 4 metric tons/year. Other companies throughout the Group are also upgrading to top runner transformers.

Energy-saving “Warashibe” budget for reducing environmental impact

The NTN Group has created an original “Warashibe” budgeting method for promoting investment in energy-saving initiatives to reduce environmental impact. A special budget has been created to account energy costs saved by energy-saving initiatives. The costs accrued in the budget are added to the following year’s budget. This budgeting method is being used at all business sites in Japan.

The Iwata Works Needle Roller Bearing Plant has reduced power consumption by installing energy saving system which connected to 80 air conditioning outside units. The system is composed of a master unit and slave units and P.C. and centrally controls air conditioning power. Six business sites (Kuwana Works, Okayama Works, Nagano Works, NTN Mie Corporation, NTN Kinan Corporation and NTN Noto Corporation) have saved energy by upgrading about 540 fluorescent, mercury and other conventional lights to LED models. These activities reduced power consumption by 990,000 kWh in the fiscal year ended March 31, 2018 (equivalent to a CO2 emissions reduction of 377 metric tons/year). We are making further energy-saving efforts, and expect the new energy-saving budget for the fiscal year ending March 31, 2019 to grow 80% from the previous year.

NTN-SNR Cevennes plant installs solar panels

The NTN-SNR Cevennes plant in France has renovated its parking lot with the addition of a 5,000 m2 solar paneled roof containing 3,049 solar panels. The parking lot holds 360 four-wheel and 22 two-wheel vehicles. The panels went into operation in October 2017. They have a rated output of 842 kW, and are expected to generate about 1.01 million kWh/year of electricity. The panels should be able to provide about 3.5% of the plant’s power needs, reducing annual CO2 emissions by about 500 metric tons. The plant has also added charging stations for EVs in the parking lot and is planning to add more to accommodate the coming EV era.

Solar panels installed in the Cevennes plant parking lot

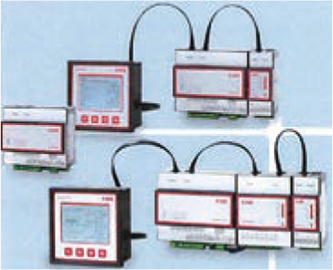

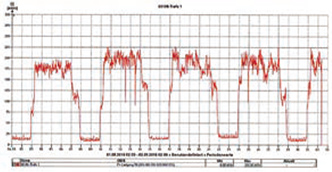

Power monitoring/management equipment and inverter-controlled air compressors at NTN Antriebstechnik G.m.b.H.

The NTN Group is working on cutting power consumption worldwide. German subsidiary NTN Antriebstechnik G.m.b.H. (NTN-AT) installed inverter-controlled air compressors in the fiscal year ended March 31, 2018, succeeding in reducing its power consumption by about 380,000 kWh/year (equivalent to a CO2 emissions reduction of about 180 metric tons/year). The planning and implementation of this power-reduction initiative was assisted by a system installed in 2015 that provides constant monitoring and management of each-process specific power consumption quantities. This system was also utilized in planing and implementing initiatives to readuce power consomption as well as verifying the effects thereof.

Power monitoring/

management equipment

Power consumption transition

NTN Kugellagerfabrik (Deutschland) G.m.b.H. Stabilizes Indoor Temperatures with Heat-resistant Paint on Roof

Lacking air conditioning equipment, NTN Kugellagerfabrik (Deutschland) G.m.b.H. feared that summertime changes in indoor temperature would worsen the work environment and machinery precision. In November 2016, the company stabilized its indoor temperatures by applying a heat-resistant paint to the 840 m2 roof of their precision angular bearings department where high-precision work is demanded. The paint has reduced the roof surface temperature by 12.9°C, the indoor temperature by 1.4°C to their peak values. It has created an environmentally friendly and pleasant work environment that saves energy and electricity.

NTN Kugellugerfabrik (Deutschland) G.m.b.H.

NTN-LYC (Luoyang) Bearing Corporation Adds Inverter Control to Compressors and Pumps

NTN-LYC (located in Luoyang, China) has managed to reduce its power consumption by about 150,000 kWh/year (a CO2 reduction of about 7 metric tons/year) by adding inverter control equipment to air compressors and heat treatment cooling system pumps.

Shanghai NTN Corporation Upgrades to High-efficiency Equipment for Climate Control and Water Cooling/Heating

With stricter environmental regulations recently being enforced in China, the government’s environmental authority has been requesting companies to help reduce CO2 emissions by upgrading aging equipment to high-efficiency models with low CO2 emissions. Shanghai NTN has upgraded equipments in a number of its facilities to high-efficiency models that save energy equivalent to a CO2 emissions reduction of about 1,600 metric tons/year. The company has upgraded air conditioning equipment in the office of 1st Plant Building and office Building and cold/hot water generators and pumps of 1st Plant Building.

High-efficiency pumps of 1st Plant Building

NTN Driveshaft, Inc. (NDI) Reduces Compressed Air Leakage

NDI has been working on reducing compressor power consumption by using leak detectors to check for leaks in the compressed air used at its plant. Sixty-two air leaks have been detected and remedied this fiscal year alone, reducing compressor power consumption by about 1.86 million kWh/year (equivalent to an annual CO2 reduction of about 1,326 metric tons). The use of leak detectors to reduce air compressor leakage is already underway at all our business sites in Japan, and will be expanded to other overseas business sites.

Promotion of CO2 reduction in logistics

■NTN LOGISTICS CO.,LTD. Reduction in truck transport

With the operation of the heat treatment factory of NTN Noto Works in July 2017, an integrated production system for industrial bearings was established in Hokuriku and Noto district, and the heat treatment completed products traditionally transported from Mie Prefecture Kuwana District to Hokuriku / Noto area, and it has reduced CO2 emissions in logistics.

■NTN LOGISTICS CO.,LTD. Improve logistics efficiency by introduction of module cardboard

We have adopted a module cardboard box that unifies the planar dimensions (vertical and horizontal) of the cardboard box for product packaging and only types of height as NTN's new standard outer packaging box from this fiscal year. By adopting the module cardboard box, packaging the product efficiently reduces the amount of use of the outer packaging box, as well as improving the efficiency of truck transportation and consolidation storage inside the warehouse by consolidating box types, and it has reduced CO2 emissions. We will work on improving logistics efficiency.

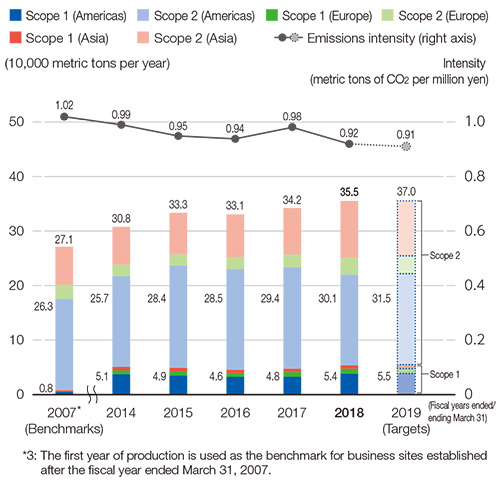

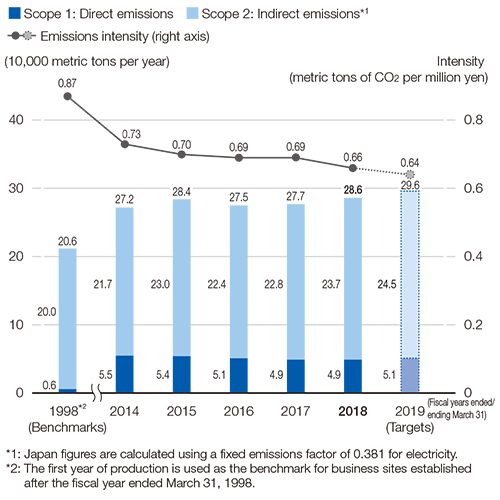

CO2 Emissions/Emissions Intensities

■CO2 Emissions/Emissions Intensities (Japan)

■CO2 Emissions/Emissions Intensities (Overseas)