CSR activities in FY2017

Management and Reduction of Environmentally Hazardous Substances

The NTN Group is managing and reducing environmentally hazardous substances while complying with worldwide laws and regulations.

Response to Environmental Regulations

The NTN Group complies with chemical substance restrictions around the world by keeping a close watch on changing restrictions and constantly testing for what substances are contained in the raw materials, parts, and materials it procures. We strive to manage and reduce the amount of environmentally hazardous and harmful substances we use.

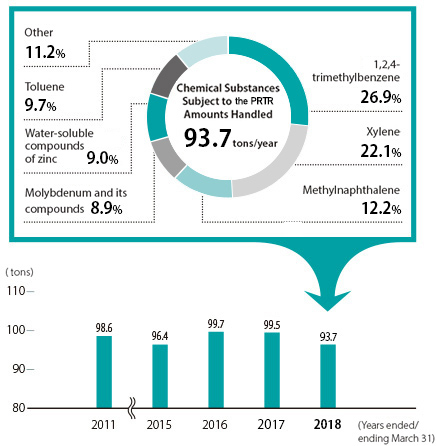

Reducing the Use of Chemical Substances Subject to the PRTR

We are committed to reducing the amount of hazardous chemical substances used in our Group’s production processes in Japan and are seeking less harmful substitutes for the hazardous chemicals that we continue to use. The target chemical substances are used in our production processes; several of the six substances shown in the chart below (‘Chemical Substances Subject to the PRTR Amounts Handled’) account for about 90% of the total, and in order to reduce the amounts of the substances used, we will introduce substitutes for the target substances we use in small quantities. Moreover, in order to reduce the total volume handled, we are promoting changes to both our work processes and the substances used.

Chemical Substances Subject to the PRTR Amounts Handled

Preventing Phthalate Ester Contamination

Phthalate esters will be added to the list of substances banned by EU RoHS directives on July 22, 2019. A large number of manufacturers have responded by announcing a delivery ban beginning one year earlier on July 22, 2018.

Anticipating the change in attitude toward phthalate esters, NTN has been working on using substitutes in production processes since 2014. We have banned their sale in principle since April 2018. The chemical properties of phthalate esters cause migration and transfer of other substances that come into contact with them, resulting in reference levels of these other substances being exceeded. We have therefore raised employee awareness of the need to work on preventing contamination from not only purchased parts, but also from NTN and supplier processes. This fiscal year, we plan to install phthalate ester analysis equipment and start analyzing rubber, PVC and other high-risk parts during acceptance inspections.

Discarding Equipment Subject to PCB Contamination

Japan’s PCB Special Measures Act was amended in May 2016 to enable faster treatment of PCB waste. The amended law went into effect on August 1, 2016. The amendment gives prefectural governments and other agencies greater authority to demand that businesses file reports and submit to on-site inspections for unregistered waste with high PCB concentrations.

Among The NTN Group in Japan, the Kuwana Works has processed 15,240 kg of transformers containing low PCB concentrations and 793 kg of lighting ballasts this fiscal year. None of our business sites in Japan has transformers containing high PCB concentrations. We will continue to work on treating discarded equipment with low PCB concentrations next fiscal year.

Emergency Drill for Accident

All our business sites in Japan held hands-on emergency response drills to prepare for oil leaks from industrial waste facilities or oil reservoirs. The drills train employees in initial response procedures during an emergency, covering topics such as how to find leak pathways and use special tools to prevent leaks from spreading.