Construction of New Plant for Turning and Heat Treatment of Driveshaft Components in U.S.A.March 17, 2017

NTN Corporation (hereafter, NTN), together with Takao Kogyo Co., Ltd. (hereafter, Takao Kogyo) and Neturen Co., Ltd. (hereafter, Neturen), have made the decision to construct the second plant of NTK Precision Axle Corporation (hereafter, NTK), a joint venture in Anderson, Indiana for the purpose of increasing production capacity of driveshaft components in U.S.A.

1. Purpose of constructing NTK 2nd Plant

One of the basic policies raised in the Medium-term Management Plan “NTN 100” is “Manage Profitability,” and NTN has been tackling “Structural Reform of the Driveshaft Business” as part of this major theme. In this theme, NTN especially has been focusing on improving profits. To achieve this, NTN has been making efforts to limit the effects of exchange rate fluctuations and business environments by increasing the ratio of local procurement in regions where demands are increasing.

With continuing strong demand for automobiles in U.S.A., the new plant of NTK is to be constructed for the purpose of increasing capacity of the turning and heat treatment processes for shafts that are key components of driveshafts. The new plant will cover turning and heat treatment processes for shafts, and will be constructed on the western side of NTN Driveshaft Anderson, Inc. (NDA), the finished product of driveshaft plant that was established in 2015.

In addition to production that has been covered entirely in U.S.A., construction of the new plant will also consolidate production of shafts that had been sourced from overseas and externally. This will make products more cost competitive, as well as accelerate transformation for “NTN driveshafts' achieving World's No. 1 customer satisfaction level” by ensuring a more stable supply system.

2. Future plans

The construction is scheduled to begin in April 2017, and mass-production will start in April 2018.

3. Overview of NTK 2nd Plant (new)

| (1) Location | Anderson, Indiana, U.S.A. |

|---|---|

| (2) Line of business | Turning and heat treatment processes for driveshaft components (shafts) |

| (3) Site area | Approximately 162,000 m2 |

| (4) Total floor area | Approximately 32,000 m2 |

| (5) Employees | Approximately 200 (planned for FY2021) |

Image of NTK Precision Axle Corporation 2nd Plant

Image of NTK Precision Axle Corporation 2nd Plant

4. Overview of NTK

| (1) Company name | NTK Precision Axle Corporation |

|---|---|

| (2) Location | Frankfort, Indiana, U.S.A. |

| (3) Line of business | Turning and heat treatment processes for driveshaft components and hub bearing components |

| (4) Capital | 15 million USD |

| (5) Total investment | NTN USA (100% subsidiary of NTN) 60% Takao Kogyo 20%, NETUREN USA (100% subsidiary of Neturen) 20% |

Reference

Driveshafts

Driveshafts are parts that consist of constant velocity joints (CVJ) and shafts to transmit the power of an automobile engine's rotation smoothly and constantly to the vehicle's tires, and are used for the front-wheel drive, 4-wheel drive and independent suspension systems of rear-wheel drive vehicles. The driveshafts are key parts that greatly affect a vehicle's fuel consumption and the quietness and comfort of the ride. These aspects of automotive performance are constantly in high demand.

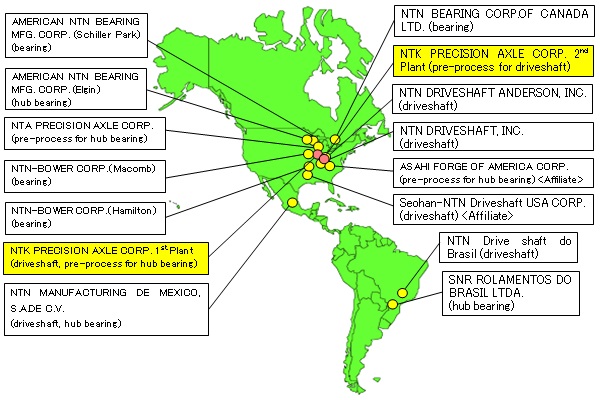

NTN production plants in the Americas