Development of “Sensor Integrated Bearing Unit” for Machine Tool SpindlesOctober 19, 2018

Industry's first product that contributes to preventing seizing with advanced condition monitoring

NTN Corporation (hereafter, NTN) has developed the “Sensor Integrated Bearing Unit” for machine tool spindles, which can prevent seizing together with advanced condition monitoring using sensing around the bearing raceway surface. Preventing bearing seizing, which causes machine tool trouble, before it occurs reduces the man-hours and cost involved in procuring parts and replacing the spindle when the machine tool spindle has seized. It decreases the time until the machine tool can resume operation, improves productivity and reduces costs. Furthermore, it contributes to an improvement in reliability as regular maintenance can be performed more accurately.

In recent years, factors such as the lack of labor shortage have created a demand for more advanced condition monitoring and control, fully automated and labor saving features that uses IoT or AI, as well as improvements in productivity. To achieve them, it is very desirable to prevent unexpected damage as well as subsequent operation stoppages and spindle replacement by quickly detecting errors with the spindle, a key component of the machine tool, and the spindle bearing. However, when generally measuring the temperature and vibration at spindle outer diameter surfaces, it is difficult to quickly detect errors such as sudden temperature rises at the bearing. This is because the measurement position is not close to the bearing raceway surface contrary to the advantage that the sensor can be installed easily.

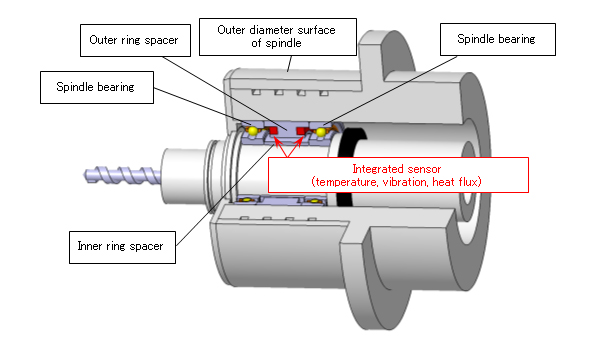

The developed “Sensor Integrated Bearing Unit” for machine tool spindles has a sensor built into the outer ring spacer adjoining the bearing. The sensor measures the bearing's temperature, vibration and heat flux*1 near the bearing raceway surface. In comparison with measurements at the outer diameter surface of spindle, the sensor can measure the condition of the bearing to a high degree of sensitivity. Measuring the heat flux enables to detect errors before the bearing seizing. This is because this measurement can read changes in the condition of the bearing quicker and more accurately than measuring just temperature or vibration. In comparison with measuring the temperature at the outer diameter surface of spindle, the measurement is approximately 40 times more sensitive based on evaluation tests in NTN. This makes it possible to achieve advanced condition monitoring of machine tool spindles and prevent damage due to bearing seizing. This product is the industry's first bearing unit for machine tool spindles that includes heat flow sensor*2.

NTN will exhibit this product at the “29th Japan International Machine Tool Fair (JIMTOF2018)” to be held at Tokyo Big Sight from November 1 to 6, and will propose it to machine tool manufacturers and spindle manufacturers.

- The amount of heat that passes through a unit area per unit time

- The heat flow sensor has multiple thermocouples arranged in series built into it. In comparison with temperature sensors configured with only a single thermocouple, this makes high sensitivity measurement possible

Features

| 1. | Provide advanced condition monitoring with sensor built into the outer ring spacer adjoining the bearing |

|---|---|

| 2. | Prevent damage before it occurs due to seizing by quickly detecting changes of the heat flux with the heat flow sensor (The percentage rise of the heat flux before seizing occurs is 40 times more than that of general measurement of the temperature at outer diameter surface of the spindle) |

Application

Machine tool spindles (machining center, lathes, multi-function machines) etc.

Inquiries about this release

Product photo

“Sensor Integrated Bearing Unit” for Machine Tool Spindles

“Sensor Integrated Bearing Unit” for Machine Tool Spindles

Construction

Construction of “Sensor Integrated Bearing Unit” for Machine Tool Spindles

Construction of “Sensor Integrated Bearing Unit” for Machine Tool Spindles(cross-sectional view)

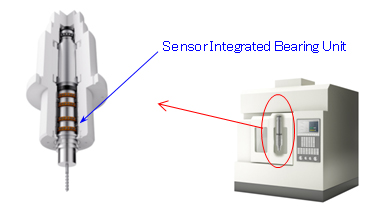

Position where product is used

Machine tool and bearing (machining center)

Machine tool and bearing (machining center)