Development of “Auto Tensioner with the Variable Damper Mechanism for ISG-Equipped Engine”November 2, 2015

[Delivers stability when starting ISG-equipped engines*1 and low fuel consumption when driving!]

NTN Corporation (hereafter, NTN) has developed the “Auto Tensioner with the Variable Damper Mechanism for ISG-Equipped Engine” that automatically adjusts the tension of accessory belts to suit engine conditions.

The number of automobiles that use idling stop mechanisms, which stop the engine when the vehicle is stationary such as when waiting for traffic lights, has increased in recent years, with the aim of reducing fuel consumption. Idling stop mechanisms detect when the driver is going to take off again and then restart the engine. The “ISG system” is the main method of doing so, where the generator (power generator) also acts as the starter (starter motor). Yet auto tensioners that had been used until now to adjust the tension of accessory belts in ISG systems could only be set to one fixed tension, whether that was with sufficient tension required for restarting the engine after idling stop, or maintaining a lower tension to help improve fuel efficiency when driving normally.

The newly developed “Auto Tensioner with the Variable Damper Mechanism for ISG-Equipped Engine” automatically adjusts the tensioner to the optimum setting to suit the engine conditions, giving ISG-equipped automobiles both greater reliability when restarting the engines, and improvement of fuel efficiency when driving.

The developed product is a hydraulic auto tensioner, and improvements made to the internal design have resulted in two oil channels with different channel resistance from the previous single oil channel. The structure of these oil channels allows the tension to be switched automatically to suit the direction of force being applied by the accessory belt. This means a relatively low tension can be applied when driving to improve fuel efficiency, while also ensuring a high level of tension is available at any moment that the engine needs to be restarted. A common design has been used with NTN conventional products that do not have a switching mechanism, to retain compatibility when installing the product.

Belt-driven ISG systems do not require major changes to the accessory belt layout design in conventional engines, and are capable of restarting engines quickly and quietly. They are also used in mild hybrid*2and other vehicles, and are expected to see increased utilization into the future.

By proposing the developed product to customers and marketing it globally, NTN will contribute to improvements in fuel efficiency of automobiles powered with ISG engines.

NTN exhibits the developed product at the “44th Tokyo Motor Show 2015” held at Tokyo Big Sight from October 29 to November 8.

- Abbreviation of Integrated Starter Generator. Motors with an integrated generator and starter motor.

- Hybrid vehicles that use the engine as the main power source, with relatively small batteries and motors providing assistance.

Features

Better fuel efficiency and a high level of stability

| (1) Better fuel efficiency | maintains a low belt tension during normal driving |

|---|---|

| (2) High level of stability | instantly generates high tension when restarting with ISG |

Applications

Tension adjustments of automobile engine accessory belts

Inquiries about this release

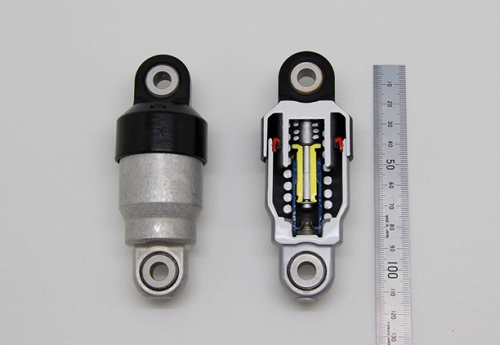

Product photo

Auto Tensioner with the Variable Damper Mechanism for ISG-Equipped Engine (left)

Auto Tensioner with the Variable Damper Mechanism for ISG-Equipped Engine (left)

and cutaway model (right)

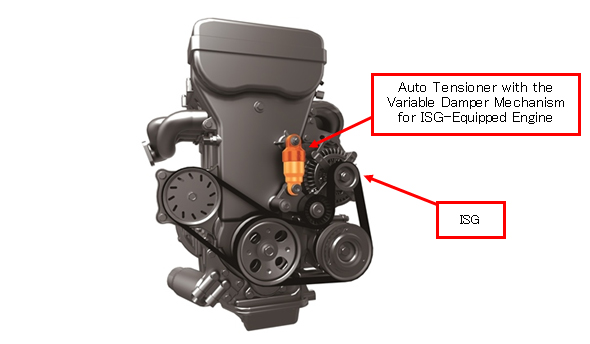

Applicable parts

Accessory belt system

Accessory belt system