April 16, 2008

Development of “MnS blended oil- impregnated sintered bearing”

-Low friction-sliding bearing with superior corrosion, seizure and wear resistances

NTN Corporation in conjunction with Nagoya Municipal Industrial Research Institute (NMIRI) has developed a stainless, corrosion resistant and low friction oil-impregnated sintered bearing. This new bearing contains manganese sulfide (MnS), which provides excellent lubrication properties while preventing seizure and wear. Manufacture and supply of this new bearing is underway.

The base material utilized in sintered bearings is either bronze or steel and they generally contain carbon (C), molybdenum disulfide (MoS2) or lead (Pb) acting as a solid lubricant. However, when a sintered bearing incorporates a base material of stainless steel containing C or MoS2, a compound is formed during the sintering process that is actually harder than the base material. This harder material attacks the mating shaft and is therefore not suitable as a sliding bearing. Furthermore, lead while providing excellent lubrication properties, is restricted world wide as a harmful substance to humans.

In response to these developments, NTN and NMIRI developed a low friction, oil-impregnated sintered bearing incorporating a base material of stainless steel containing a moderate amount of MnS, a material that provides resistance to seizure and wear due to its superior lubricating properties. Additionally, sulfur contained in MnS forms an extreme-pressure film as the bearing slides during operation, while not disturbing the chromium oxide in stainless steel required for good corrosion resistance.

The MnS-blended stainless oil-impregnated sintered bearing will operate successfully in corrosive environments, providing low friction operation for extended periods. It is now being produced commercially and is being utilized in “IT equipment”, replacing the stainless steel anti-friction bearing.

This bearing will be exhibited at the 17th Motion Engineering Japan 2008 to be held on April 16 to 18 in the Makuhari Messe.

[ Features ]

a. Corrosion resistance properties

Stainless steel is used as a base material

b. Seizure and wear resistance property

Superior seizure and wear resistances property because of sulfur film formed by blended-manganese sulfide during sliding.

[ Available size ]

Bearing bore : φ1~10mm

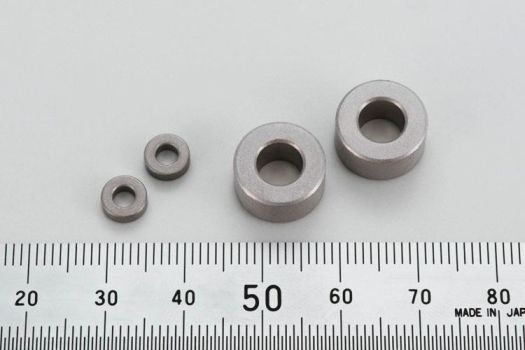

[ Product photo ]

| Bearing dimension, | Large type: Bore 6mm x O.D. 12mm x Width 6mm |

| Small type: Bore 3mm x O.D. 6mm x Width 2mm |