NTN Exhibits at the China CNC Machine Tool Fair “CCMT 2018”March 30, 2018

| Date | April 9 (Mon) to 13 (Fri), 2018 |

|---|---|

| Venue | Shanghai New International Expo Centre Shanghai, China |

| Booth No. | N5-A201 |

NTN will run a booth at the China CNC Machine Tool Fair “CCMT 2018.”

With the theme “Navigate Your Future ∼NTN ULTAGE∼,” various bearings from the ULTAGE* series will be on show assembled onto main shafts, including the ULTAGE Small Size High Speed Angular Contact Ball Bearing for Machine Tool Spindles and Machine Tool Main Spindle Bearing with Air Cooling Spacer.

A wide range of other products will also be exhibited, such as the Bearing Technical Calculation System for Machine Tool Spindles and composite material products for machine tools. There will also be a dynamic exhibit of the Parallel Link High Speed Angle Control Equipment suited to high-speed, high-precision positioning.

We look forward to seeing you at the event.

* ULTAGE is the name for NTN's goal of achieving the ultimate performance with precision bearings, and expresses the “Ultimate” performance on any type of “Stage.”

Main exhibits

ULTAGE Series of Precision Roller Bearings for Machine Tools

Precision bearings that support high efficiency processing, high reliability, high quality processing and environment-conscious design required for machine tools. Demonstrates excellent ability due to such factors as the adoption of seals on both sides, special grease, special material/surface modification and also the optimization made to the internal bearing design.

ULTAGE Small Size High Speed Angular Contact Ball Bearing for Machine Tool Spindles

Adopts a newly designed seal that retains a large volume of grease inside the bearing, without obstructing dust prevention functionality and cooling with compressed air, to improve grease retention and ensure the steady flow of compressed air. In addition, we have devised a grease lubricated position and volume, which achieves long life. Furthermore, by adopting a processing method that improves the precision of the bearing raceway surface, we have reduced vibrations by approximately 50% in comparison with conventional types.

Machine Tool Main Spindle Bearing with Air Cooling Spacer

Reduces the inner and outer ring temperature difference during high speed rotation by adopting an “air cooling spacer” that applies a unique air cooling technology to the machine tool main spindle bearing. This improves the high speed rotational performance by 20% in comparison with existing parts (ultra-high speed angular contact ball bearings) and achieves a dmn value* of 2.1 million with air oil lubrication and fixed position preload, which provides the highest level of high-speed rotational performance in the world.

* An indicator that expresses the rotational performance of bearings and is bearing pitch circle diameter (mm) × rotational speed (min-1)

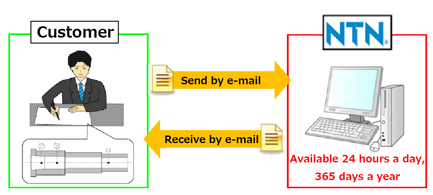

Bearing Technical Calculation System for Machine Tool Spindles

A system that customers can use to automatically calculate factors such as the main spindle rigidity and bearing operating life for precision roller bearings in a short amount of time. The main spindle layout has been increased from 10 to 13 patterns and the security level has also been improved. Contributes towards further reducing development lead times for machine tools.

Parallel Link High Speed Angle Control Equipment

A compact device with operation over a wide range of moving angles (two degrees of freedom) for high-speed, high-precision positioning. Stage and rotating axis combinations allow workpieces to be approached from various directions. Its structure allows the end effector and wiring to be placed within the hollow space inside links for a more compact device and wiring that is easier to use.