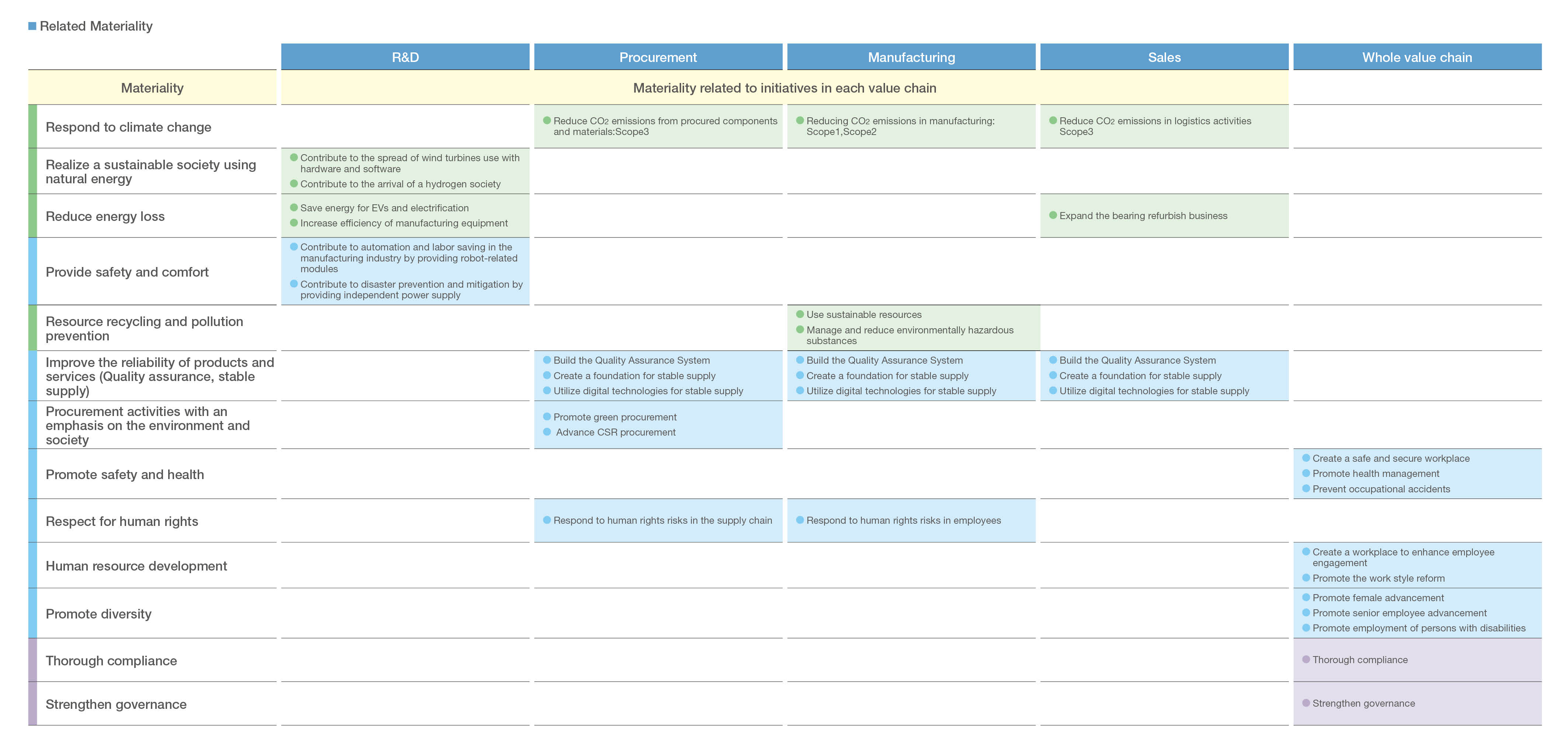

Strengths and Materiality Initiatives along the Value Chain

The Group is promoting initiatives in line with the materiality to respond to the SDGs by leveraging its strengths in R&D, procurement, Monozukuri(Manufacturing), sales, and each of these processes. In developing business activities based on our corporate philosophy of “we shall contribute to the international society by creating new technologies and developing new products,” we create value in the value chain, leading to sustainable growth.

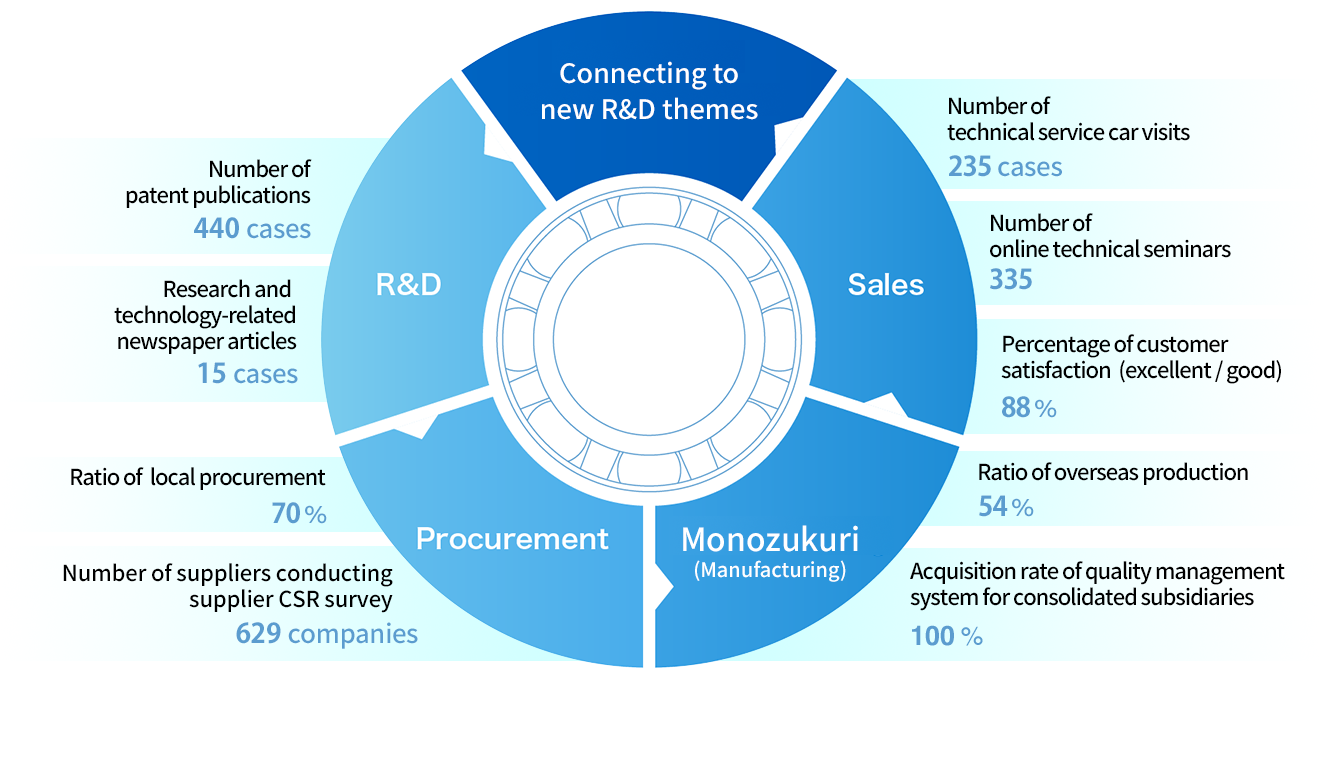

NTN Value Chain

Strengths that create value

R&D

We are building a technological foundation for sustainable growth by enhancing the value of existing products through deep plowing and deepening our core technologies and developing products in new areas that capture changes in the business environment.

In the automotive field, we are developing products that contribute to electrification, and have developed a bearing that achieves a dmn value* of 2.2 million as a further high-speed response to “High-Speed Deep Groove Ball Bearings for EVs and HEVs,” which are designed for high-speed motor rotation due to the downsizing of electric drive unit products.

In the industrial machinery field, the use of robots at production sites is accelerating and work operations are becoming more diverse. We have developed a “Multi Track Magnetic Encoder Integrated Rolling Bearing” that can detect the rotation speed, direction, and absolute angle of robot joints, enabling improved joint motion accuracy and a reduction in the number of parts.

In the new area of business, we have developed a “Talking BearingTM” that incorporates a power generation unit and wireless device into an existing rolling bearing and wirelessly transmits information on temperature, vibration, and rotational speed to help realize advanced condition monitoring of equipment.

*: dmn value: An index of bearing rotational performance;

bearing pitch circle diameter (mm) x rotational speed (min-1)

・Results produced

Number of patent publications: 440

Research and technology-related newspaper articles: 15

Procurement

In Japan, procurement from overseas suppliers is progressing and global transactions are expanding. In accordance with the Procurement Policy established in response to each of the SDGs, we will pursue international and open procurement by promoting local procurement and procurement in optimal locations from a global perspective, and aim for stable procurement that responds immediately to market fluctuations, while emphasizing quality and price advantages and delivery reliability. In addition, by complying with laws regulations and ethical standards and conducting fair and equitable transactions, we will not only ensure the trust of our customers and society, but also improve the competitiveness of our business partners and continue to achieve “sustainable growth” together with them.

We will contribute to the creation of a “sustainable society and environment” by promoting “green procurement,” in which we procure from suppliers that comply with environmental laws and regulations and are committed to environmental conservation, with consideration given to reducing their environmental impact. We will deepen mutual understanding with our business partners through business transactions and strive for coexistence and co-prosperity based on trust.

・Results produced

Ratio of local procurement: 70%

Number of business partners conducting CSR questionnaires for suppliers: 629

Monozukuri (Manufacturing)

As part of production reforms, we are promoting streamlining to optimize the entire process, including logistics, and are working to improve throughput by reducing inventories and lead times. Manufacturing sites are promoting DX to efficiently collect and analyze information, visualize problems, and quickly make improvements to increase productivity. We will also promote low-carbon manufacturing to achieve carbon neutrality, which will lead to increased corporate value, customer satisfaction, and profit generation.

In terms of quality, we are striving to ensure stable quality throughout the “process” from the development stage to the manufacturing process and delivery of products to customers. Specifically, we are “building in quality” throughout the company by conducting design reviews at each step, strengthening risk analysis when changes occur, and conducting quality audits at manufacturing sites. We promote the establishment of a global quality assurance system by incorporating remote audits, improving processes, and providing quality guidance to local employees when starting up production overseas.

・Results produced

Ratio of overseas production: 54%

Acquisition rate of quality management system for consolidated subsidiaries: 100%.

Sales

In response to the rapid shift to EVs in the automotive market and the growing need for electrification in the industrial machinery market, we provide high value-added module products in line with customers’ new product development, and service solutions for wind turbines that utilize IoT technology to monitor the condition with bearings. We are developing consulting-based sales activities. In addition, for existing models currently in mass production, we are striving to take meticulous measures to ensure stable supply on a global basis amid the ever-changing global situation. For the aftermarket, we not only sell products, but also provide technical services such as demonstrations and workshops on how to handle bearings to increase customer satisfaction. In the fiscal year ended March 31, 2023, we held more than 300 technical seminars in remote format in Japan and abroad as the COVID-19 pandemic continued.

As customers’ needs are drastically changing due to the paradigm shift in the external environment, we will strive to improve our NTN brand and further enhance customer satisfaction by contributing to the realization of a sustainable society as characterized by carbon neutrality, as well as by increasing the functionality and added value of our products.

・Results produced

Number of technical service car visits: 235

Number of online technical seminars: 335

Percentage of customer satisfaction (excellent/good): 88%